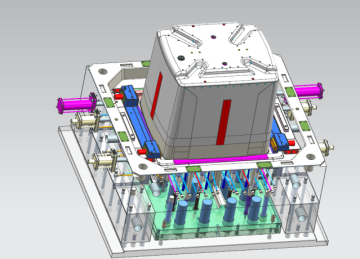

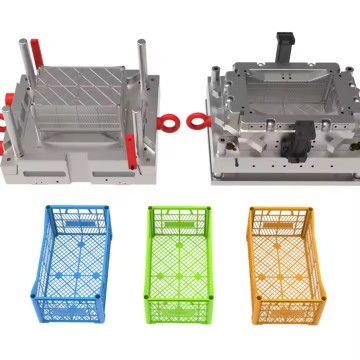

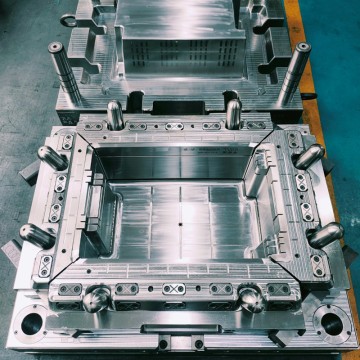

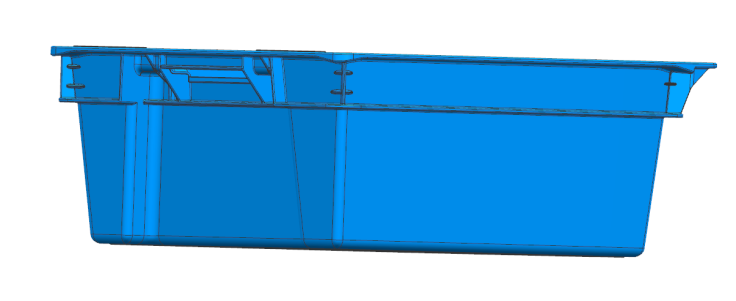

Precision Crate Mould-Heavy-Duty Stacking & Nesting Plastic Crate Molds for Industrial Storage and Smart Logistics

Product Description

Core Advantages of Our Crate Mould Technology:

Unmatched Structural Integrity: Utilizing premium grade steels and advanced flow simulation, our molds produce crates with superior impact resistance and load-bearing capacity, ensuring safe transport of heavy goods.

Space Optimization Design: We specialize in molds for both rigid stacking crates for maximum stability and space-saving nesting crates that reduce empty return transport costs by up to 70%.

Enhanced Productivity: Features like conformal cooling channels and automated ejection systems significantly reduce cycle times, lowering your per-unit production cost and boosting output.

Tailored for Your Industry: Whether you need vented crates for agricultural produce, sealed crates for automotive parts, or hygienic, easy-clean designs for food and beverage, we provide fully customizable solutions.

Sustainable Manufacturing Ready: Our molds are optimized for using recycled polypropylene (rPP) or polyethylene (rPE), supporting your environmental goals without compromising product quality.

Partner with us to transform your storage and logistics. From initial design consultation to final production, we provide the engineering expertise and reliable moulds that form the foundation of a smarter, stronger supply chain.

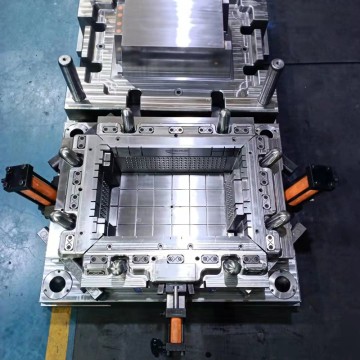

Workshop Images

FAQ

A: The key difference lies in the part design and mold complexity. Stacking crate molds focus on creating a rigid lip or rim that allows secure, vertical stacking under load. Nesting crate molds are engineered for tapered sidewalls, enabling crates to fit inside one another when empty. This requires precise draft angles and often more sophisticated ejection systems to handle the deeper draw. We analyze your logistics workflow to recommend the optimal design.

A: We employ a multi-step engineering process. First, Moldflow analysis simulates plastic flow and cooling to identify potential areas of uneven thickness or sinks. Second, our mold design incorporates strategic cooling line placement and adjusted rib-to-wall thickness ratios (typically 40-60%). Finally, we use controlled injection speed and packing pressure profiles during trials to achieve perfect fill and dimensional stability.

A: The most vulnerable areas are ejector pins (due to frequent friction), slide mechanisms (for handles or undercuts), and cavity surfaces (from abrasive fillers in recycled material). We mitigate wear by using hardened tool steels (e.g., H13) for cores and cavities, applying specialized surface coatings like DLC (Diamond-Like Carbon), and designing easily replaceable standard components for maintenance.

A: Absolutely. A crucial part of our design consultation is understanding your downstream automation. We can design molds for automatic robot part removal, include specific locating features for robotic grippers, and ensure crate dimensions and rigidity are compatible with high-speed conveyor systems and automatic palletizers.