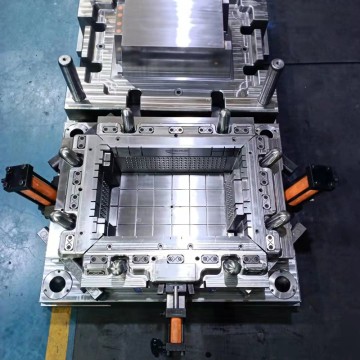

Top Plastic Pot Mould Manufacturers & Suppliers for Quality Products

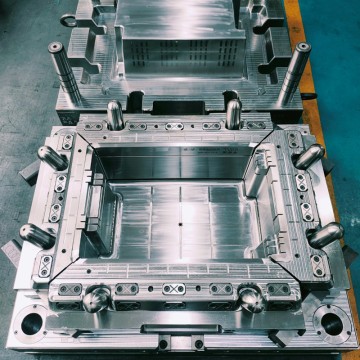

As a prominent manufacturer in the industry, we recognize the critical role that high-quality Plastic Pot Moulds play in your operations. Our molds are expertly crafted with precision to deliver exceptional durability and efficiency tailored for manufacturers who demand reliable solutions. At Taizhou Huangyan Xintong Mold Co., Ltd., we are committed to utilizing advanced manufacturing processes that can accommodate both large and small production needs. The right mould can greatly influence your production efficiency, and our dedicated team works closely with you to fulfill your unique requirements. With years of expertise, we guarantee that our plastic pot moulds not only meet but surpass industry standards.Best Way To Choose Plastic Pot Mould Factory Manufacturer

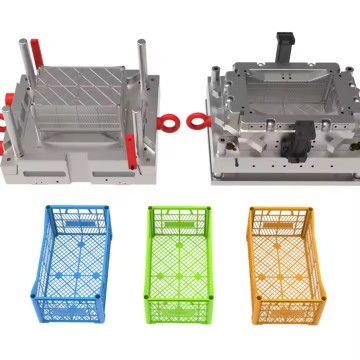

When it comes to selecting the best plastic pot mould factory manufacturer, the decision-making process is crucial for global buyers seeking quality and reliability. With expertise spanning diverse industries such as medical equipment, logistics, home furniture, and electrical appliances, partnering with a reputable mould manufacturer provides significant advantages. Look for factories that not only have a proven track record but also understand the specific demands of your industry. This ensures that the products meet the highest quality standards and regulatory requirements. Choosing a plastic pot mould manufacturer involves evaluating several key factors. First, consider their experience and portfolio. A manufacturer with a strong history in custom molding solutions can better understand your needs, offering tailored designs that enhance functionality and aesthetics. Additionally, modern manufacturing capabilities and technology adoption will impact the quality and efficiency of production. Lastly, always check for customer testimonials and case studies that can give insight into their operational reliability and client satisfaction. In an increasingly interconnected world, having a dependable partner for your plastic mould needs is essential. By aligning with a factory that values quality, innovation, and customer support, you can confidently move forward in your procurement process, ensuring that your final products meet consumer expectations while standing out in a competitive market.

Best Way To Choose Plastic Pot Mould Factory Manufacturer

| Criteria | Description | Rating (1-5) | Notes |

|---|---|---|---|

| Experience | Years in the industry and expertise in plastic pot mould manufacturing. | 4 | Look for at least 5 years of experience. |

| Quality of Materials | The grade and durability of raw materials used. | 5 | Verify suppliers for high-quality resins. |

| Customization Options | Ability to provide custom mould designs and sizes. | 4 | Ensure they can meet specific design needs. |

| Technical Support | Availability of support for technical issues and guidance. | 5 | Look for factories offering responsive support services. |

| Production Capacity | Volume of production they can handle per order. | 3 | Ensure they can meet your production demands. |

| Client References | Feedback from previous clients regarding their satisfaction. | 4 | Request to see testimonials or case studies. |

| Pricing | Cost competitiveness compared to industry standards. | 4 | Ensure prices reflect quality and service. |

Methods To Choose Plastic Pot Mould Supplier Factory

E

Emma Martinez

The product exceeded my expectations in terms of quality. The after-sales service staff were not only professional but also went above and beyond to ensure my satisfaction.

29 May 2025

Z

Zoe Martinez

Amazing product quality! The professionalism of the customer service team contributed immensely to my positive experience.

25 June 2025

D

Daniel Adams

Quality is exceptional! The professionalism displayed by the support staff made for a smooth experience.

09 June 2025

J

Jameson Lee

Impressive quality! The after-sales service exceeded my expectations with their professionalism.

21 June 2025

M

Maverick White

High-quality items! The after-sales service team was exceptionally responsive and knowledgeable.

20 June 2025

E

Elena Reed

Incredible quality! The attentiveness and professionalism of the customer service team was exceptional.

26 June 2025