Manufacturing and advantages of plastic pallets

Advantages of plastic pallets: 1. Easy to operate; 2. Wide applicability; 3. Convenient for handling operations; 4. Can be combined with anti slip rubber to ensure that materials will not slip during handling and transportation; 6. Long service life and can be reused after damage; 7. Plastic pallets are safe, hygienic, insect proof, and do not require repair.

Disadvantages of plastic pallets: Due to the influence of production molds, the structure and size of plastic pallets have poor flexibility, and production enterprises must continuously develop and gradually enrich their product types. But for special size requirements, sometimes they cannot be met. Due to the low repairability of damaged plastic pallets, they can only be scrapped after a certain degree of damage, but the waste can be recycled.

Plastic pallets are widely used in the warehousing and transportation industry as storage and logistics products. Plastic pallets can generally be divided into three categories based on the manufacturing process: Injection Molded Pallets, blow molded pallets, and vacuum formed pallets. These three types of trays are collectively referred to as plastic trays, as they are all related to plastic technology. Therefore, when purchasing tray molds, attention should be paid to the manufacturing process of the trays.

The blow molding equipment used for blow molding trays is generally a large hollow molding machine, which uses HDPE as raw material. Therefore, the quality of its products is good compared to plastic trays. Moreover, blow molded tray products have novel and unique shapes, reasonable structural design, groove design on the surface, good anti slip performance, and no corner residue. And its molding process is fast and thorough; The product is fully formed, with stable internal quality and performance. In particular, blow molded trays have many characteristics such as aging resistance, corrosion resistance, moisture resistance, oil resistance, and easy cleaning and disinfection. They are increasingly used in the fresh cold chain and food industry.

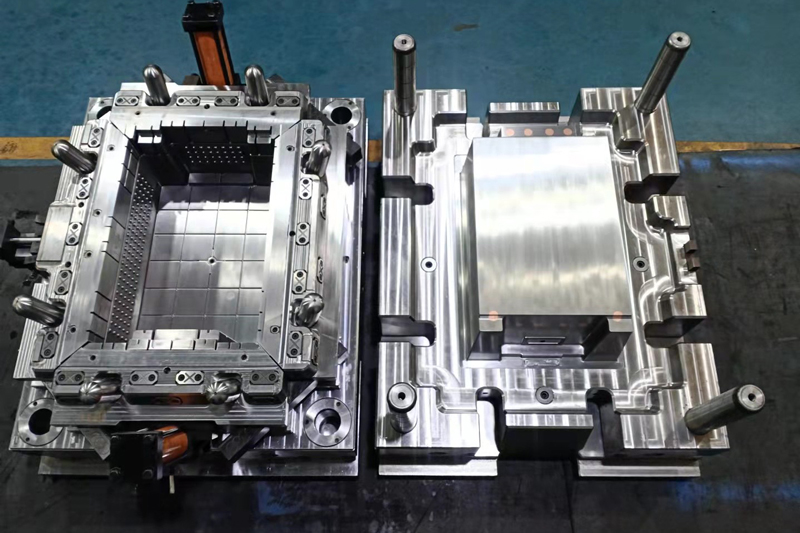

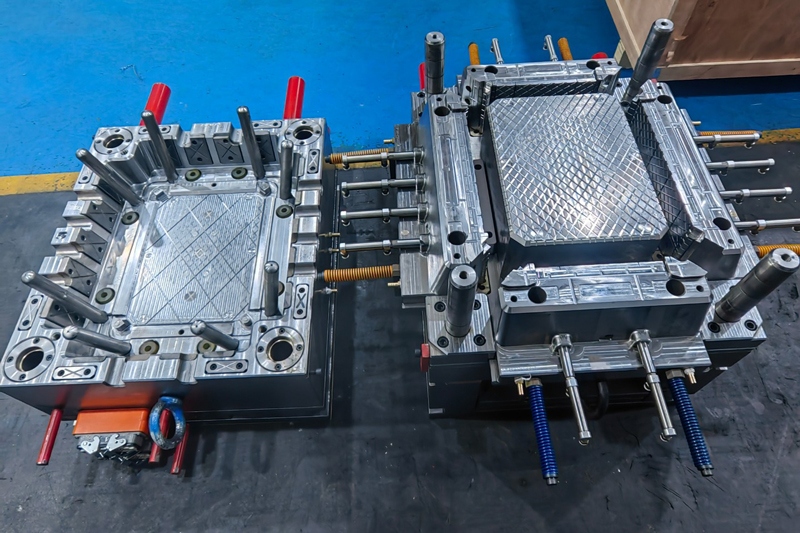

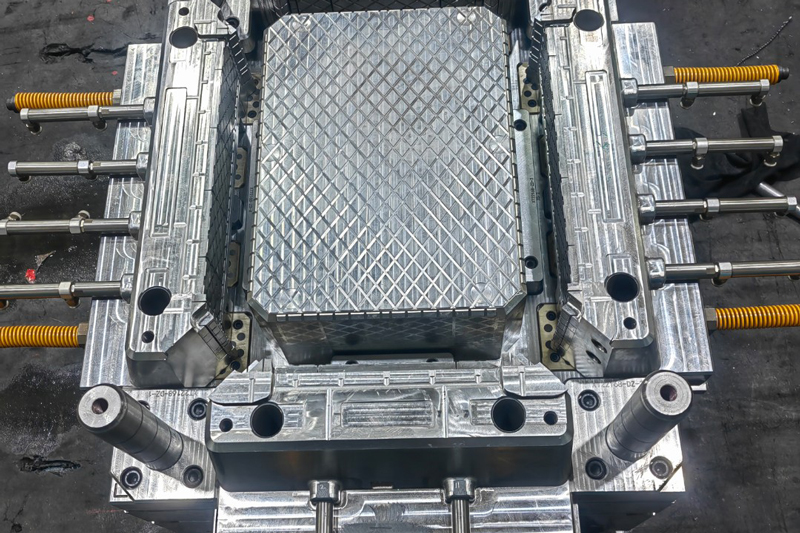

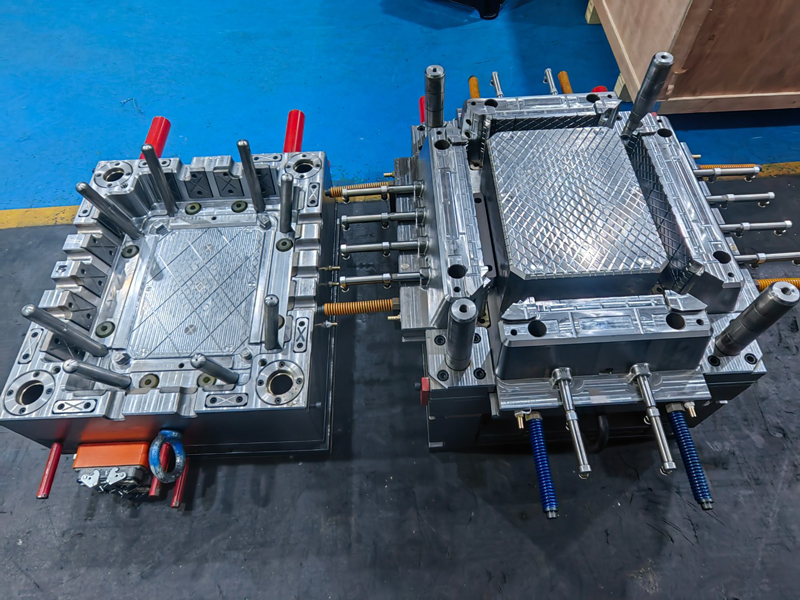

When making injection molded trays, the plastic raw materials are melted and injected into the mold. Once the melted plastic enters the mold and cools down, a workpiece with the same shape as the film cavity is obtained. This process is usually completed by injection molding machines. The injection molded tray has a hard texture, stable chemical properties, is non-toxic and odorless, and will not have any adverse effects on the product. After installing steel pipes, the load-bearing capacity of injection molded pallets can be greatly increased. Injection molded pallets can be put on shelves or transported with pallets, but the reason limiting their large-scale use is their high production cost.

Blister tray refers to a tray processed by vacuum forming technology, which is a rapidly developing plastic processing method used to produce molded products. Some plastic trays are processed and formed using this process, which mainly involves heating flat plastic hard sheets to soften them, and then cooling and forming them on the surface of the mold using vacuum adsorption. In addition, the cost of the vacuum forming process mold is lower than that of injection molding, making it suitable for small-scale production. A single mold can produce products of different materials and thicknesses. The vacuum forming process has limitations on the shape of the tray, and the dimensional accuracy of the product is inferior to injection molding. Mainly used for small irregular products in industries such as electronics, toys, stationery, cosmetics, and health products, mostly disposable items.

We have many years of experience and mature technology in the design and processing of tray molds. At present, the main plastic pallets are injection molded pallets and blow molded pallets, among which Tianzi injection molded pallets, Chuanzi injection molded pallets, and nine foot blow molded pallets are more common.