01

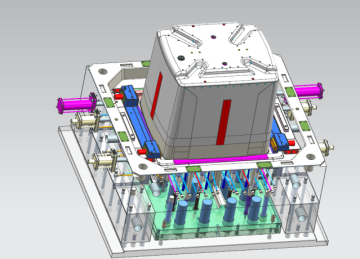

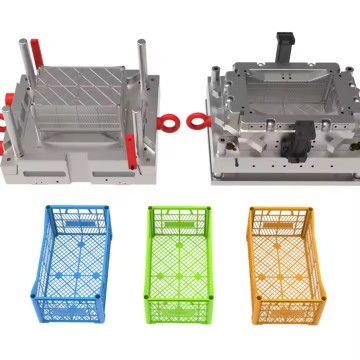

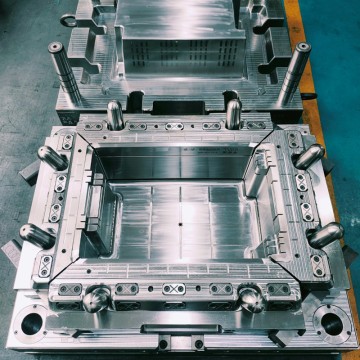

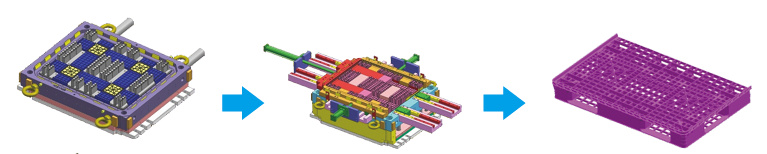

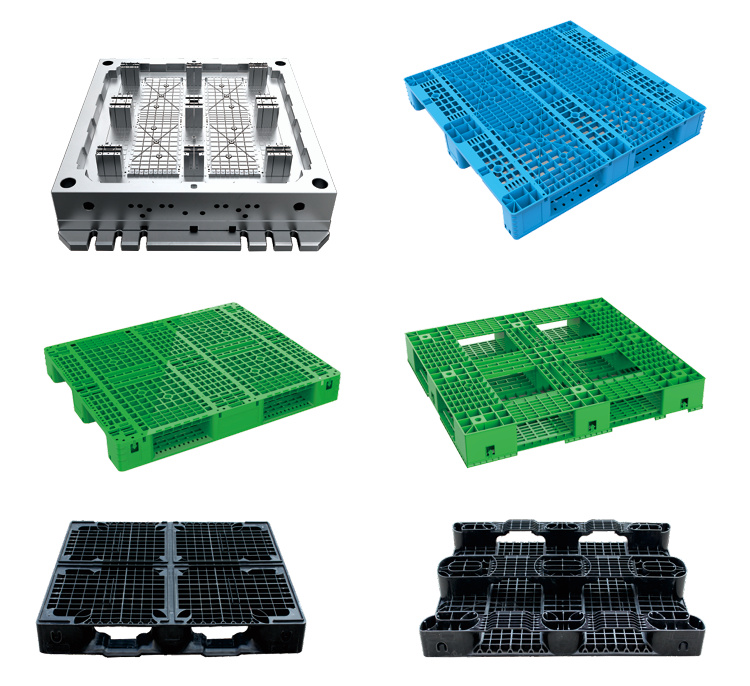

Four Windows Logistic Plastic Pallet Injection Moulds

Production Details

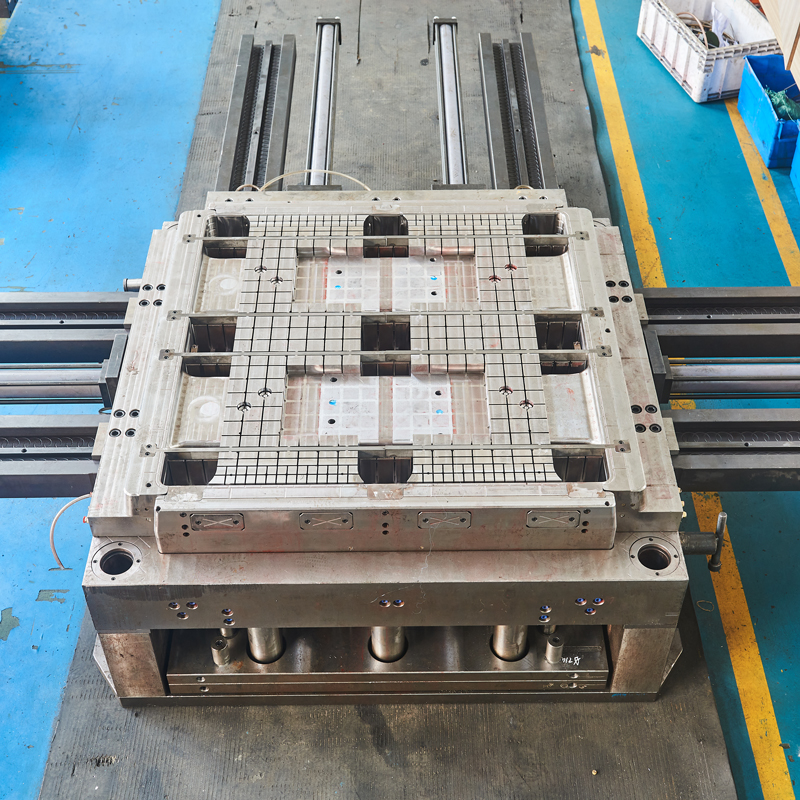

Product Pictures

Product feature and application

● The temperature resistance range is usually -25 ℃ to+50 ℃ (some high-quality materials such as polypropylene Double-deck Plastic Pallet can be used normally within the temperature range of -30 ℃ to 65 ℃, but should avoid direct sunlight exposure and proximity to heat sources).

● The process application is an automated line. Manual labor only requires loading the processed iron material onto the fixture and feeding it; All other loading, processing, and unloading tasks are completed by robots, and the program is inputted through programming. Reduce labor costs, improve accuracy, and reduce production cycles by half.

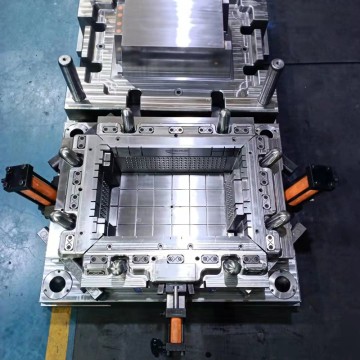

Workshop Images

FAQ

Q1: How can i get the quotation?

We will submit the quotation in 24 hours if getting detailed information during working days. In order to quote for you earlier, please provide us the following information together with your inquiry:

1)3D Step of Files and 2D Drawings

2)Material requirement

3)Surface treatment

4)Quantity (per order/per month/annual)

5)Any special demands or requirements, such as packing, labels, delivery, etc.

Q2: How you do the quality control?

1). Materials inspection by IQC;

2)During processing, our IPQC will check the injection molded parts every

3)Hours, ensure no any rejects;

4)FQC will check the products before sending to the warehouses

5)100% inspected by QC before shipping out.

Q3: What should we do if we receive defective products?

If receive defective product, please send us the photos, we will feedback to ourengineers and QC departments and solve the problems ASAP.

Q4: How to pack the moulds and products?

1). For moulds, we will be coated one_layer anti_rust oil first, and then also will be covered thin films on the mould, finally pack into fumigation wooden case.

And as to products, we will pack into standard export cartons or as per customer's request to pack.