In the fast-paced world of logistics, packaging efficiency is paramount. Pallet Mould designs play a pivotal role in optimizing supply chains. According to a recent report by the Packaging Industry Institute, companies utilizing innovative pallet moulds can reduce shipping costs by up to 30%. This data highlights the significant impact of effective packaging solutions on overall operational efficiency.

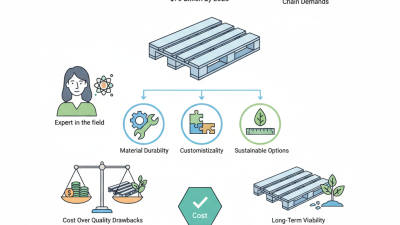

Expert John Smith, a prominent figure in the Pallet Mould industry, emphasizes, "Smart design leads to smarter logistics." His insights underline the importance of tailored pallet moulds for various products. As businesses evolve, the need for customized designs grows. Traditional pallet moulds may not meet the demands of diverse goods. This presents an opportunity for stakeholders to reassess their strategies.

Many companies still rely on outdated pallet moulds. This can lead to inefficiencies and increased wastage. The shift toward modern designs requires investment and creativity. Evaluating existing packaging methods can yield remarkable results. As the market shifts, so too must our approach to pallet mould design, striving for continuous improvement.

Pallet mould designs are crucial in the packaging industry. They play a significant role in enhancing efficiency and reducing waste. With various designs available, each serves a unique purpose. Traditional designs often lack flexibility, limiting their usability for different products. This can be frustrating for manufacturers.

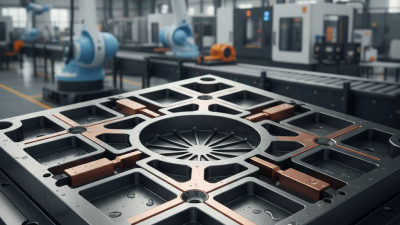

Modern pallet moulds focus on versatility. They offer innovative features that accommodate various shapes and sizes. Companies are exploring materials that improve durability and reduce environmental impact. It's essential to balance strength and weight. Heavier pallets increase shipping costs, which is a consideration many overlook.

However, not all designs are perfect. Some may not perform well under certain conditions. For instance, exposure to moisture can degrade certain plastics. This inconsistency prompts ongoing research and development. Continuous improvement is necessary to meet changing demands in the packaging market. Adapting to new technologies and consumer expectations can be challenging. Yet, it is vital for success in this competitive field.

The effectiveness of pallet moulds greatly impacts packaging solutions. A well-designed pallet mould enhances efficiency and reduces costs. Key features include durability and versatility. Durable materials withstand heavy loads over time. This longevity is crucial for ongoing operations. Versatile designs allow adaptation for various products. Flexibility in size and shape can streamline production.

Another important aspect is the ease of use. Pallet moulds should be user-friendly for quick assembly. Complicated designs can slow down the process. It's essential to avoid such pitfalls. Moreover, consider the environmental impact. Eco-friendly materials can support sustainability efforts. However, balancing durability with eco-friendliness is challenging.

Lastly, focus on maintenance requirements. Pallet moulds need regular checks to ensure optimal performance. Neglecting this can lead to inefficiencies. Maintenance should not be overlooked. It is an integral part of the entire packaging process. Emphasizing these features fosters better packing solutions. The right design choices are foundational to success.

When discussing pallet mould designs, efficiency is often key. According to recent industry reports, companies using optimized pallet moulds can increase operational efficiency by up to 30%. This improvement is critical in supply chain scenarios, where a slight delay can lead to significant losses.

Popular designs include the block, stringer, and double-face pallets. Each of these has its own strengths and weaknesses. For instance, block pallets offer greater stability, making them suitable for high-stacking environments. However, their manufacturing process can be more complex and time-consuming. On the other hand, stringer pallets are easier to produce but may not provide the same level of support. Their lower cost can tempt manufacturers to overlook durability concerns.

Not all designs suit every product type. Reports indicate that nearly 20% of pallet failures are linked to design misalignment with load specifications. This highlights the need for ongoing assessment of pallet mould designs. Practitioners must regularly evaluate their packaging solutions, ensuring they align with their logistical requirements and product characteristics.

| Pallet Mould Design | Material Used | Weight Capacity (kg) | Dimensions (mm) | Production Time (days) | Cost Estimate (USD) |

|---|---|---|---|---|---|

| Design A | HDPE | 1500 | 1200 x 800 | 15 | 2500 |

| Design B | PP | 1200 | 1000 x 1200 | 10 | 2300 |

| Design C | WOOD | 2000 | 1200 x 1000 | 20 | 3000 |

| Design D | PVC | 1400 | 1100 x 1100 | 12 | 2700 |

| Design E | ALUMINUM | 1800 | 1000 x 800 | 25 | 3500 |

| Design F | STEEL | 2200 | 1200 x 800 | 30 | 4000 |

| Design G | COMPOSITE | 1600 | 1100 x 1100 | 18 | 3200 |

| Design H | RECYCLABLE PLASTIC | 1300 | 1200 x 800 | 14 | 2400 |

| Design I | BAMBOO | 1500 | 1000 x 1000 | 22 | 2800 |

| Design J | FIBERBOARD | 1100 | 1200 x 800 | 16 | 2200 |

Modern pallet mould designs are revolutionizing the packaging industry. Innovative materials are at the forefront of this change. These materials improve durability, reduce production costs, and enhance sustainability. For instance, biodegradable plastics are increasingly popular. They offer an eco-friendly alternative to traditional materials. Lightweight composites also provide strength without the extra weight.

Recyclable materials play a vital role as well. Using them can lower the overall environmental impact. However, the challenge remains in balancing sustainability and performance. Some recyclable options may not endure heavy loads effectively. This requires ongoing research and adjustments to existing designs. Additionally, there’s a need for better waste management systems to support these materials.

As we adopt new materials, the designs must evolve. Experimentation with thermoplastics shows promise. They offer flexibility and can streamline the manufacturing process. Yet, not all designs succeed. Some prototypes fail to meet industry standards. This is a reminder that not every innovation leads to immediate success. Continuous refinement is crucial for effective packaging solutions.

The design of pallet moulds plays a crucial role in supply chain optimization. A well-crafted pallet can streamline the movement of goods. It minimizes handling time and reduces the risk of damage. When pallets are designed for specific products, efficiency increases. The precise fit ensures stability during transport, leading to fewer accidents.

However, not all designs excel in every scenario. Some moulds may limit versatility. This can lead to wasted space in transport. Inadequate designs often cause mismatched sizes. This mismatch results in inefficient stacking, increasing costs. Companies must regularly assess their pallet designs to adapt to changing needs.

Innovation in pallet moulds is essential. Lightweight materials can offer improved performance. Eco-friendly designs also matter in today's market. Nevertheless, experimenting with new materials can be risky. Manufacturers must balance durability with sustainability. Continuous improvement and adaptation are keys to success, yet self-reflection is crucial in this process. Each pallet design must be analyzed for its effectiveness in real-world applications.