In the world of construction, the Mould Bucket has become an essential tool. According to the Construction Industry Research Board, the global market for construction tools is projected to reach $65 billion by 2025, highlighting the importance of efficient equipment. Mould Buckets, designed for mixing and pouring concrete, play a crucial role in this sector.

Expert John Smith, a renowned construction industry consultant, states, “The right tools, like the Mould Bucket, can significantly enhance project efficiency.” This statement reflects the growing recognition of specialized tools. Mould Buckets are versatile, offering various applications, from concrete mixing to material transport.

However, the misuse of Mould Buckets can lead to inefficiencies. Some workers underestimate their capabilities. This oversight can result in wasted time and resources. Ultimately, understanding the Mould Bucket's diverse uses is vital for maximizing productivity on construction sites.

Mould buckets, essential in construction, serve multiple functions. They are primarily used for transporting materials like concrete, gravel, and sand. The design allows them to be lifted easily by cranes or machinery. Their tapered shape is efficient for pouring. Increased accuracy helps minimize spills and waste.

The importance of mould buckets lies in their ability to improve workflow on-site. Construction projects often face delays due to inefficient material handling. Without proper tools, workers can struggle to keep tasks moving smoothly. A lack of organization causes frustration, resulting in errors. Mould buckets help mitigate these problems by providing a streamlined process.

Despite their benefits, not all workers use mould buckets effectively. Some may fill them too much, making them heavy and hard to control. Others neglect maintenance, leading to wear and tear. These issues could slow a project down or even create hazards. Reflecting on their use can drive improvement. Ensuring that all workers understand proper techniques can enhance both safety and efficiency.

Mould buckets play a crucial role in construction, especially in concrete mixing and pouring. These containers are designed to hold and transport raw materials for concrete production. Their specific shape allows easy blending of sand, gravel, cement, and water. This ensures a consistent mix, which is vital for structural integrity. A well-mixed batch will behave predictably during pouring.

Using mould buckets can lead to efficiency in workflows. With proper handling, they minimize waste and reduce the risk of spillage. However, improper use can lead to issues like uneven mixing. It's essential to fill them correctly and avoid overloading. Weight distribution is key here. When pouring, a stable bucket can prevent accidents.

The versatility of mould buckets is notable. They can be used for various applications, from foundations to decorative paving. Yet, they require careful consideration in size and design for specific projects. A common mistake is choosing the wrong bucket for the task. Learning from such oversights can improve future project outcomes. Realizing the right approach enhances the effectiveness of mould buckets significantly.

Mould buckets are invaluable tools in construction. They enhance efficiency in material transportation, which is crucial for project timelines. Using mould buckets can streamline the movement of concrete, sand, or gravel. When workers have easy access to materials, they can maintain their momentum.

However, there are challenges when using mould buckets. If not handled properly, they can spill materials and create messes. This not only wastes resources but also poses safety hazards. Workers must be trained on the appropriate techniques for handling and transporting materials. Proper training can minimize mistakes and improve overall workflow.

Choosing the right size and type of mould bucket can also be tricky. A bucket that is too big may be hard to control, while a smaller one might require frequent trips. Balancing size and functionality is key to maximizing efficiency. Experimenting with different options can reveal what works best for specific projects.

Mould buckets are often underutilized on construction sites. They can do more than hold material. With a bit of creativity, they can enhance site organization too. According to a report by the Construction Industry Institute, poor site organization can lead to a 10-15% increase in project costs. So, optimizing how we use mould buckets makes sense.

One innovative way is to assign specific coloured buckets for different materials. For instance, blue for cement and green for aggregates. This method not only speeds up identification but also reduces time wasted searching. A simple reorganization can cut down confusion significantly. Research states that clear organization improves worker efficiency by 25%.

Another approach is using mould buckets for tools. Instead of random piles, designate buckets for specific tool sets. This reduces time spent looking for tools and keeps the site tidy. However, it's crucial to periodically review which tools are used most. Keeping seldom-used tools in buckets might lead to clutter. Reflecting on these practices can lead to more effective site management.

| Use Case | Description | Benefits | Tips for Use |

|---|---|---|---|

| Material Mixing | Used for mixing concrete, mortar, and other materials on-site. | Efficient mixing reduces waste and ensures better consistency. | Choose the right size bucket for the quantity needed. |

| Waste Collection | Collecting debris and leftover materials during construction. | Keeps the site organized and safe. | Label buckets for different types of waste for easier disposal. |

| Water Storage | Temporary storage of water for mixing or cleaning purposes. | Convenient access to water at various locations on-site. | Ensure buckets are clean to avoid contamination. |

| Tool Organizer | Storing hand tools and small equipment for easy access. | Reduces the time spent searching for tools. | Assign buckets for different tools based on trades. |

| Paint Mixing | Mixing different colors of paint or coatings. | Achieves custom colors efficiently. | Use clean buckets to avoid color contamination. |

| Cement Transport | Transporting small amounts of cement to work areas. | Minimizes spills and allows for precise application. | Secure lids if transporting over long distances. |

| Sifting Sand | Using buckets to sift through sand for cleanliness. | Improves quality of materials used in mixing. | Use a mesh bottom for better sifting. |

| Plant Watering | Carrying water to plants on construction sites. | Maintains landscaping during construction projects. | Use separate buckets for different areas. |

| Training Aid | Demonstrating mixing techniques and procedures. | Helps train new workers in a hands-on manner. | Utilize dummy materials for training sessions. |

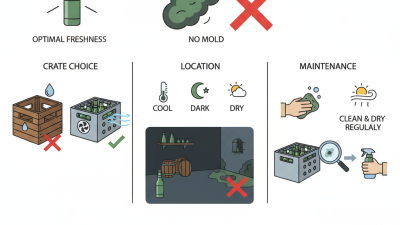

Maintaining and storing mould buckets on construction sites is crucial for efficiency. Cleanliness is priority. After each use, buckets should be thoroughly cleaned to prevent material buildup. This helps preserve their lifespan. Leaving leftover substances can also attract pests. Storing dirty buckets could lead to contamination in your next project.

Proper storage is essential for quick access. Keep mould buckets in a designated area, away from debris. This not only keeps them in good condition but also contributes to a safer site. Ideally, buckets should be stacked to save space. Ensure they are easily accessible without creating hazards. Sometimes, workers may overlook proper stacking, leading to spills or accidents.

Regular inspections are necessary but often neglected. Check for cracks or wear that could compromise the bucket's structure. A faulty bucket could lead to unwanted issues in critical moments. Neglect can result in increased costs. Taking a little time to routinely check these items will pay off in the long run. Keeping mould buckets in good shape requires diligence and a commitment to best practices.