In the rapidly evolving logistics sector, selecting the right Logistic Pallet Mould is crucial. The global pallet market is expected to grow to $70 billion by 2025, driven by the surge in e-commerce and supply chain demands. Understanding the nuances of pallet moulds can significantly enhance operational efficiency.

Expert in the field, Dr. Rachel Harmon, emphasizes, "The choice of Logistic Pallet Mould can determine the cost-effectiveness of your entire operation." Her insights underline the importance of considering material durability and customizability.

Many businesses gravitate towards cost over quality, which can yield drawbacks. Moreover, companies often overlook sustainable options, risking long-term viability. As the market evolves, embracing innovation in Logistic Pallet Mould design is essential. Balancing cost, quality, and environmental impact is a challenging yet necessary task for modern businesses.

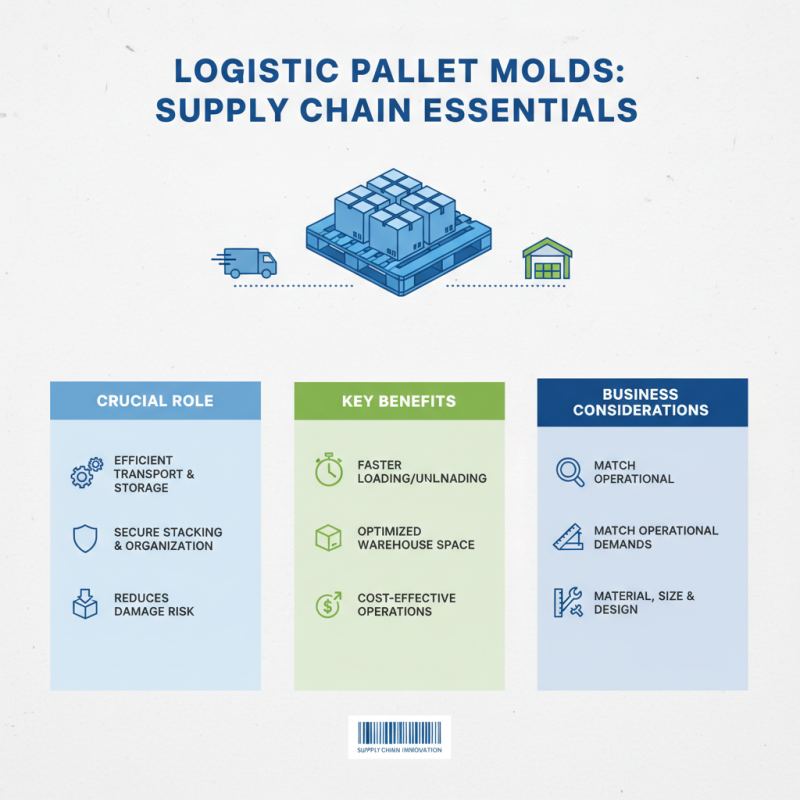

Logistic pallet moulds play a crucial role in supply chain operations. They are essential for the efficient transportation and storage of goods. These moulds help ensure that products are securely stacked and organized. Without effective pallet moulds, the risk of damage during transit increases significantly. Every business must consider the distinct demands of their operation when selecting these moulds.

The choice of material is critical. Different materials provide various levels of strength and flexibility. For instance, plastic moulds may offer lightweight yet durable solutions. On the other hand, wooden moulds might be preferable for heavy cargo, despite being bulkier. One must also reflect on the environmental impact of the materials used. Is sustainability considered in your business choices? Overlooking this can have lasting negative effects.

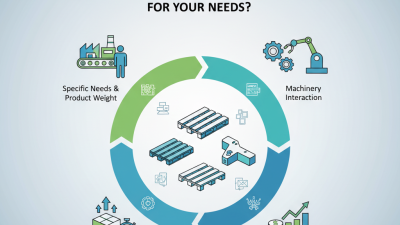

Moreover, the size and design of the mould are equally important. Customization might seem favorable but can also lead to increased costs and complexities. Finding a balance is key. Is it truly necessary to invest in custom solutions? Recognizing operational needs without over-complicating logistics is vital. Hence, careful consideration and analysis are essential when choosing the right logistic pallet mould.

When selecting logistic pallet moulds, it's important to consider key factors that align with your business requirements. Material is one crucial aspect. Pallet moulds are often made from various plastics like polyethylene or polypropylene. Each material offers different strengths and weaknesses. According to industry data, pallets made from high-density polyethylene can last up to 20% longer than those made from other materials. This durability can save costs over time.

Another significant factor is the pallet size and design. Standard dimensions often lead to compatibility issues in warehousing. Approximately 30% of logistics inefficiencies stem from using incorrect pallet sizes. Knowing your storage capacity and shipping requirements is essential. Additionally, consider the weight capacity. Moulds should support the maximum load your pallets will carry without warping.

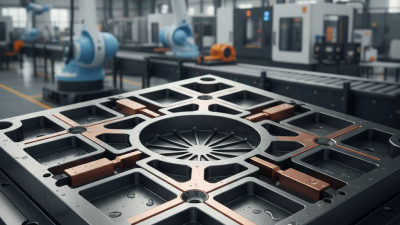

It's also vital to think about the manufacturing process. Injection moulding is common and allows for intricate designs. However, this method can be costly. Sometimes, alternative methods like blow moulding offer more cost-effective solutions. Awareness of these manufacturing techniques can guide you toward better decisions. Balancing cost and efficiency often presents challenges. Understanding these elements can shape your approach to choosing the right logistic pallet mould for your business needs.

When selecting a logistic pallet mould, understanding the different types and their specific applications is crucial. There are primarily three categories of pallet moulds: standard, bespoke, and collapsible. Standard pallet moulds are widely used in warehouses and are ideal for bulk storage. The Global Logistics Report indicates that around 70% of companies prefer standard pallets due to their reliability.

Bespoke moulds allow customization according to specific requirements. They are essential for industries that manage delicate or uniquely shaped products. For instance, the pharmaceutical sector often requires custom pallets to ensure safety during transport. Meanwhile, collapsible moulds offer a space-efficient solution for return logistics. These can reduce shipping costs by up to 25%, according to industry estimates.

It's worth pondering the balance between cost and functionality. While lower-priced options might seem appealing, they can impact durability. Companies can face issues like frequent replacements. Ultimately, choosing the right logistic pallet mould means weighing the benefits of each type against your business needs. It’s not just about immediate savings; it’s also about long-term reliability and efficiency.

| Type of Logistic Pallet Mould | Material Used | Applications | Advantages |

|---|---|---|---|

| Standard Plastic Pallet Mould | High-Density Polyethylene (HDPE) | General warehousing and distribution | Durable, lightweight, resistant to chemicals |

| Euro Pallet Mould | Wood or Plastic Composite | Transportation within Europe, retail, and automotive industries | Standardized size, easy handling and storage |

| Heavy-Duty Pallet Mould | Reinforced Polymer | Heavy machinery and goods storage | High load capacity, long service life |

| Stackable Pallet Mould | Plastic | Retail and food industry | Maximizes storage and space efficiency |

| Collapsible Pallet Mould | Metal or Heavy-Duty Plastic | E-commerce and reverse logistics | Space-saving when not in use, easy handling |

When selecting logistic pallet moulds, material choices play a crucial role in both durability and cost-effectiveness. Different materials offer varying benefits. For instance, plastic pallets are lighter and resistant to moisture, but metal is stronger and lasts longer. However, the initial cost of metal can be higher. It's essential to weigh these factors against your business needs.

Consider the environment in which the pallets will be used. Will they face heavy loads daily? Or will they be stored away? This decision dramatically influences your material choice. While metal might be ideal for heavy loads, plastic may suffice for lighter items. Remember, durability often comes with a price tag. Investing in quality materials can lead to savings in the long run.

Here are some tips: Assess the expected usage frequency first. Evaluate your budget constraints before making any decision. Also, think about resale value. Sometimes, a higher upfront cost can result in better returns if you choose wisely. It's all about balancing durability and cost. Take time to reflect on your long-term goals for your operation.

Proper maintenance of logistic pallet mould is crucial for its longevity. Regular cleaning is essential to remove debris and contaminants. According to industry reports, 30% of mould failures stem from inadequate cleaning. Implementing a consistent cleaning schedule can mitigate this risk significantly. Always use non-corrosive cleaners to avoid damaging the mould surface.

Temperature control is equally important. Moulds should be stored in a climate-controlled environment. Extreme temperatures can warp or crack moulds. A report from the International Plastics Association indicates that nearly 20% of moulds deteriorate due to improper storage conditions. Monitoring humidity levels is vital, as excessive moisture can lead to corrosion.

Lastly, regular inspections can help identify minor issues before they escalate. Missing fasteners or small cracks can severely impact the mould's performance. A proactive approach can increase the lifespan of logistic pallet mould by 40%. Investing time and resources into these maintenance practices pays off in the long run. It's critical to reflect on current practices. Are they effective enough to prevent costly mould replacements?