In today's competitive manufacturing landscape, choosing the right equipment is crucial. The Filter Plate Mold stands out for its efficiency and versatility. According to a recent report by MarketsandMarkets, the global filtration market is projected to reach $35 billion by 2026, highlighting the growing need for optimized filtration processes.

Using a Filter Plate Mold can significantly enhance production efficiency. This tool allows for seamless integration into various manufacturing processes. A well-designed mold improves product consistency, reducing waste. However, not every mold meets industry standards. It's essential to evaluate quality and performance carefully.

Moreover, the selection of a Filter Plate Mold can impact operational costs. An inferior mold may lead to higher maintenance and replacement costs. Therefore, investing in a high-quality mold is a decision worth contemplating. Ultimately, the right choice can drive better outcomes in production and sustainability.

Filter plate molds play a crucial role in various production environments. These molds are essential for manufacturing filter plates used in numerous applications. They are commonly found in industries such as wastewater treatment, food processing, and pharmaceuticals. The demand for efficient filtration systems drives the need for reliable molds.

These molds are designed for precision and durability. They create filter plates that can handle high pressures and temperatures. In many cases, the design must be customized to fit specific requirements. This can lead to challenges during the production process. Each project may require adjustments, testing, and modifications. These potential issues underscore the importance of skilled engineers in the mold-making process.

While filter plate molds offer many advantages, they also come with challenges. The initial cost of production can be high. Companies may struggle with long lead times and technical obstacles. Additionally, maintaining quality across batches is vital. Understanding these factors can help businesses make informed choices about using filter plate molds for their production needs.

Filter plate molds play a crucial role in industrial production. They offer significant advantages that enhance efficiency and output quality. One major benefit is their ability to separate contaminants effectively. This process ensures that the final product meets the necessary purity standards. Many industries rely on this feature. Without it, product quality may suffer.

Another key advantage is the reproducibility of the molds. They can produce consistent results, which reduces variation in production runs. This consistency leads to fewer defects and waste. However, some users find it challenging to maintain the molds properly. Regular maintenance is essential to ensure optimal performance. Neglecting this aspect can lead to unexpected downtime.

Using filter plate molds can also reduce production costs over time. Their durability means fewer replacements are needed. However, initial costs may deter some manufacturers. Balancing the upfront investment with long-term savings requires careful consideration. Ultimately, the choice to use filter plate molds should reflect a commitment to quality and efficiency in production processes.

Choosing a filter plate mold involves careful consideration of several key factors. The material of the mold is essential. Different materials can impact durability, flexibility, and the overall quality of the end product. Metal molds tend to offer longevity, while plastic molds may provide cost benefits.

Tips: Look for high-quality materials that resist wear and tear. Evaluate your production volume to determine the best fit.

The mold design is another critical element. It should match the intricacies of your production requirements. Complex designs may lead to longer production times but can enhance product performance. Be mindful of your production speed and efficiency.

Tips: Test various designs before settling. Small adjustments can make a significant difference.

Finally, it's vital to consider maintenance. Some molds require more upkeep than others. Regular maintenance can prolong the life of a mold and maintain product quality. A poorly maintained mold can lead to defects and increased costs.

Tips: Schedule routine checks and cleanings to enhance performance. Neglecting maintenance can result in costly repairs.

Filter plate molds play a crucial role in various industries. They are often used for separating solids from liquids. The effectiveness of these molds largely depends on the materials they are made from.

Common materials for filter plate mold manufacturing include polypropylene and polyethylene. These plastics are favored for their resistance to chemicals and moisture. They provide durability, making them suitable for high-volume production. Metal options like stainless steel and aluminum are also common. They offer strength and temperature resistance but can be heavier and more expensive.

However, not all materials suit every application. Some may degrade under certain conditions, impacting performance. It’s vital to choose wisely based on specific needs. Cost and longevity play a significant role in this decision. Sometimes prototypes reveal shortcomings in material choices. Re-evaluation may be necessary. Balancing quality and cost can be challenging but crucial for successful production.

| Material Type | Characteristics | Applications | Cost Efficiency |

|---|---|---|---|

| Polypropylene (PP) | Lightweight, chemical resistant, good thermal stability | Filtration in food and beverage industries | Low cost, effective for high-volume production |

| Polyethylene (PE) | Flexible, durable, moisture resistant | Water treatment and industrial filter applications | Cost-effective for various applications |

| Polyvinyl Chloride (PVC) | Strong, impact-resistant, good insulation properties | Used in chemical processing and filtration systems | Moderate cost, high durability |

| Stainless Steel | Corrosion resistant, robust, high temperature tolerance | Heavy-duty industrial applications | Higher initial cost, long-term durability savings |

| Aluminum | Lightweight, good thermal conductivity, resistant to corrosion | Used in applications requiring weight efficiency | Cost-effective for specific applications |

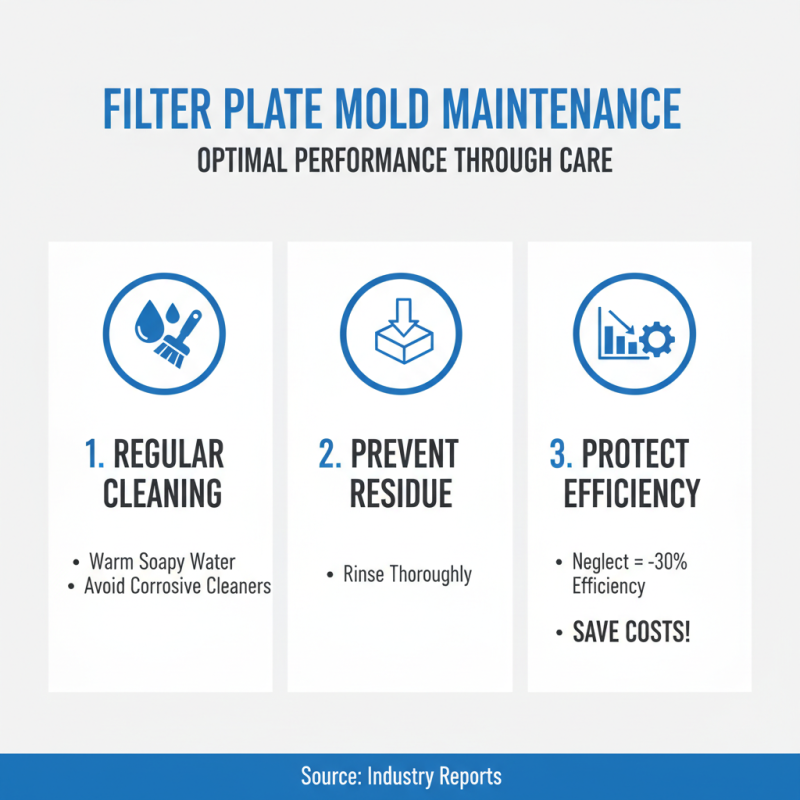

When considering filter plate molds, proper maintenance is key for optimal performance. Regular cleaning is essential. Avoid corrosive cleaners, as they can degrade the mold material. Instead, use warm soapy water. Rinse thoroughly to prevent residue buildup. Industry reports suggest that neglected molds can decrease filtration efficiency by up to 30%. That’s significant.

Inspecting the molds frequently is crucial. Look for signs of wear or damage. A small crack can lead to larger issues over time. Research shows that proactive maintenance extends mold lifespan by an average of 20%. This means less downtime and reduced production costs. Keeping a maintenance log can also help track performance and issues.

Storing the molds correctly matters, too. Humidity and temperature fluctuations can adversely affect the materials. A controlled environment is ideal. Use protective coverings to prevent dust accumulation. Dust can compromise mold accuracy. It’s a simple step that can have a profound impact on longevity and efficiency.