Welding has seen remarkable advancements over recent years. The introduction of specialized equipment, such as the Welding Pallet, has significantly improved efficiency. According to a recent industry report, the global welding market is expected to reach over $30 billion by 2025, emphasizing the growing relevance of effective welding solutions.

Expert and welding consultant John Anderson states, "A well-structured Welding Pallet can transform the workflow in any welding operation." His insights highlight the importance of utilizing such equipment to maximize productivity. Many shops still overlook the potential benefits, which can lead to wasted time and resources.

Utilizing a Welding Pallet effectively involves more than just having the right equipment. It requires an understanding of material handling and workspace organization. Investing time in training and proper setup is crucial. However, some may underestimate the need for ongoing training, leading to missed opportunities for improvement. The right practices can yield significant results.

Welding pallets can be a valuable tool for beginners. Understanding how to use them is crucial. A welding pallet serves as a stable surface for your projects. This stability can enhance the quality of your work.

For someone just starting, it’s important to maintain a clean workspace. A cluttered area can lead to mistakes. Make sure to organize your materials. Lay out your tools and equipment in a logical manner. This small step may seem basic, but it makes a huge difference.

Familiarize yourself with safety measures. Ensure you wear gloves and protective gear. Always check your equipment for defects. Ignoring these points can lead to accidents or poor welds. Mistakes will happen; acknowledge them and learn. Reflection on missteps is essential for growth in welding skills.

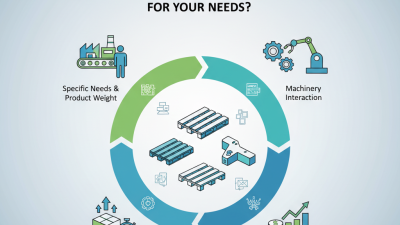

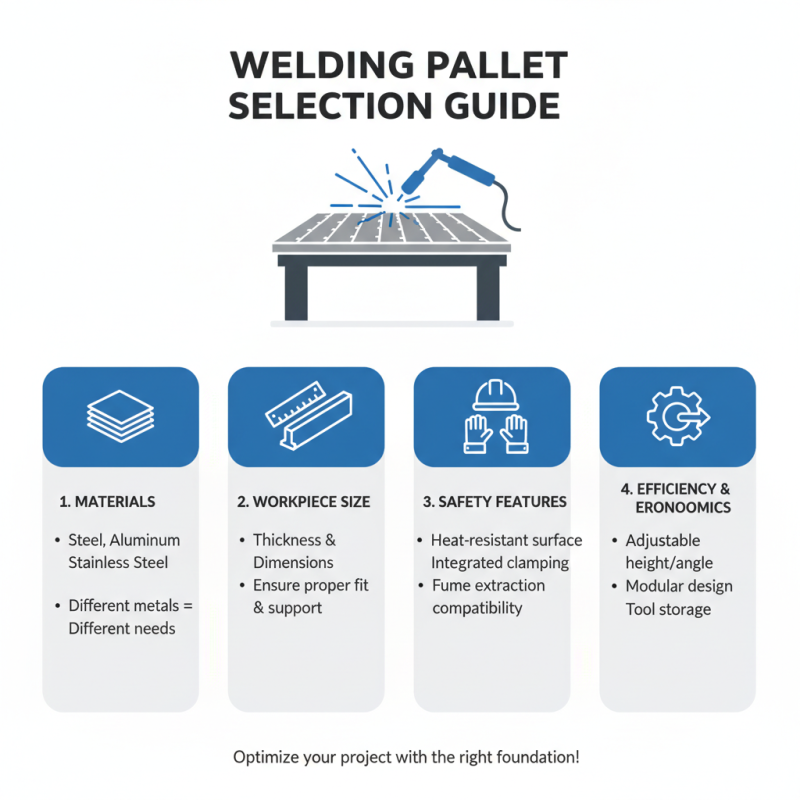

Choosing the right welding pallet for your project needs is crucial for efficiency and safety. Start by identifying the materials you will work with. Different metals have unique welding requirements. For instance, aluminum may require a different approach than steel. Consider the thickness of your workpieces as well. A pallet must accommodate various sizes effectively.

Look for features that enhance usability. Adjustable height, for example, can improve accessibility during welding. Be mindful of the weight limit as well. Overloading a pallet can lead to issues. An unstable platform can result in accidents. Check the design for any sharp edges or hazards that could pose a risk during operation.

Many welders overlook maintenance. A clean pallet can lead to better performance. Rust or debris can interfere with the welding process. Ensure that your chosen pallet is easy to clean. Reflect on your past projects and consider what worked and what didn’t. This reflection can guide your decision-making. Making the right choice will enhance your welding experience and project outcomes.

Using welding pallets can enhance your fabrication projects, but safety should always come first. Always wear protective gear. This includes gloves, helmets, and flame-resistant clothing. Ensure your workspace is well-ventilated. Fumes produced during welding can be harmful. If you feel dizzy or lightheaded, take a break.

Check your pallet for any signs of damage before use. A cracked or weak pallet can lead to accidents. Use clamps to secure materials tightly. This prevents unexpected movements during welding. Keep a fire extinguisher nearby. Being prepared is key in case of emergencies.

Stay focused while working. Distractions can lead to mistakes. If you’re tired or unwell, consider postponing your task. The quality of your work depends heavily on your concentration. Sometimes, rushing can lead to an oversight. It’s essential to reflect on your methods and always prioritize safety over speed.

Welding pallets can greatly enhance your productivity. To maximize efficiency, start by organizing all necessary tools. Place them within arm's reach. This reduces time spent searching for equipment. A clean workspace boosts focus and minimizes accidents.

Another tip is to monitor your welding parameters closely. Small adjustments can lead to better results. If you notice uneven welds, take a moment to reassess your technique. Sometimes, stepping back helps refine your approach. Ensure your materials are clean and free from contaminants. Ignoring this can compromise your work.

Finally, don’t rush the process. Welding requires precision. It's tempting to speed up to meet deadlines, but this can lead to mistakes. Review your work often. Reflection leads to improvements. Learn from each project to build on your skill set effectively.

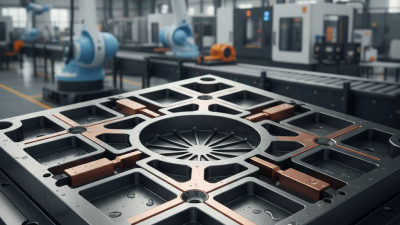

Maintaining your welding pallet is crucial for its longevity and performance. Regular cleaning is essential. Remove any welding spatter or debris after each use. This prevents buildup that can affect the pallet's integrity over time. Use a wire brush or scraper for stubborn spots. Be mindful of sharp edges, as they can cause injuries or damage to your tools.

Inspect your welding pallet frequently. Look for wear and tear, such as cracks or bent edges. Address small issues before they become significant problems. A simple touch-up with a welding rod can extend the life of your pallet. Store your pallet in a dry environment to prevent rust. Consider using a protective cover if it is stored outdoors. It’s easy to overlook these steps, yet they are vital for effective use.

Lubricate moving parts regularly. This helps prevent sticking and wear. Dust and grit can ruin smooth operations. If you notice unusual sounds during use, pause and check for any loose components. Ignoring these issues can lead to accidents or costly repairs. Keeping an organized workspace also contributes to better maintenance. It helps you identify problems quickly. Simple habits can make a significant difference in the lifespan of your welding pallet.

| Tip Number | Maintenance Tip | Frequency of Maintenance | Notes |

|---|---|---|---|

| 1 | Clean the pallet regularly | Daily | Remove any slag, dust, or debris. |

| 2 | Inspect for damages | Weekly | Check for cracks or bent surfaces. |

| 3 | Lubricate moving parts | Monthly | Use high-temperature grease. |

| 4 | Store the pallet properly | Always | Keep in a dry, controlled environment. |

| 5 | Avoid overloading the pallet | Always | Refer to the manufacturer's weight limits. |

| 6 | Check for rust | Weekly | Use a wire brush to remove rust. |

| 7 | Ensure proper ventilation during use | Always | Prevents overheating and fumes. |

| 8 | Train staff on proper usage | Annually | Periodic training sessions recommended. |

| 9 | Replace worn parts | As needed | Timely replacement can prevent bigger issues. |

| 10 | Document maintenance activities | Ongoing | Keep records for future reference. |