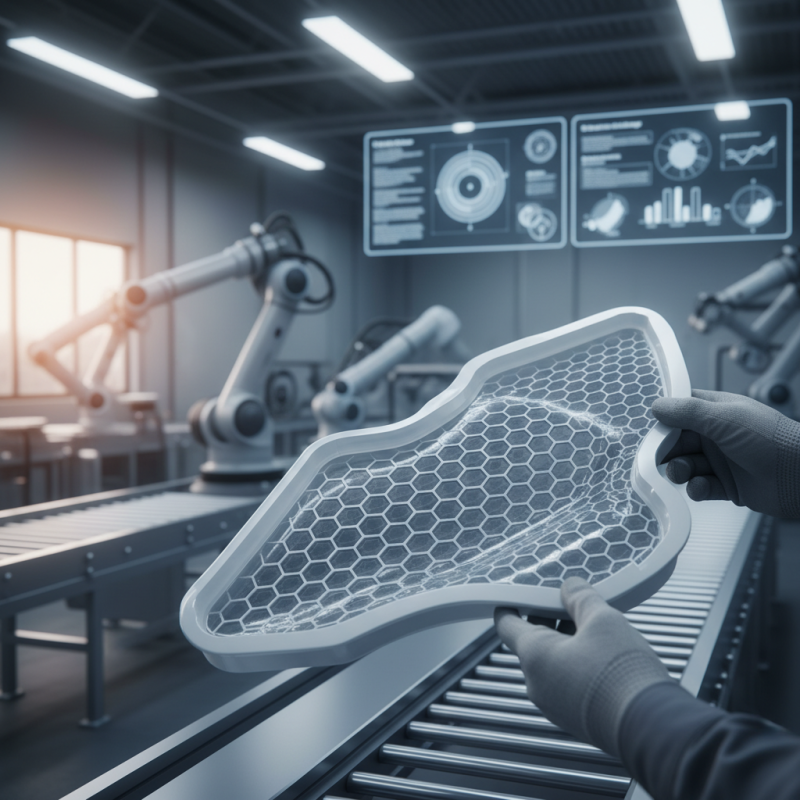

Choosing the right Light Weight Mold for your project can significantly impact its success. According to industry reports, the demand for lightweight materials has surged. In fact, the global market for lightweight molds is expected to grow by 5.2% annually until 2026. This shift is driven by the need for efficiency and cost-effectiveness in manufacturing.

Selecting the appropriate mold involves understanding various factors. Material choice, design specifications, and project requirements are crucial. Working with lightweight molds can minimize material fatigue, leading to longer service life. However, mistakes in selection could lead to increased costs or project delays. Examining case studies reveals that 30% of projects overspend due to improper mold choices.

Ultimately, careful consideration of your project's specific demands is essential. While lightweight molds offer many advantages, recognizing their limitations is crucial. A balanced approach will ensure that you make an informed decision, optimizing both performance and budget.

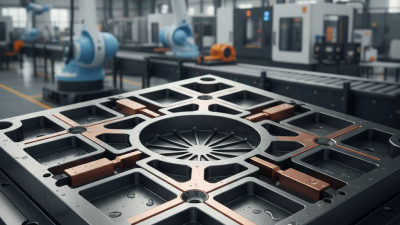

When exploring lightweight molds in manufacturing, several fundamental aspects come into play. Lightweight molds offer significant advantages over traditional materials. They enhance efficiency and reduce production costs. Many manufacturers opt for these molds to streamline their workflows. However, understanding the material properties is crucial.

When choosing a lightweight mold, consider its strength and durability. Some materials may be easier to handle but can compromise the mold's longevity. Balancing weight and performance is not always straightforward. Companies may struggle with this decision.

Another factor to consider is the specific project needs. Not every lightweight mold suits every application. Often, manufacturers must experiment to find the best fit. This trial-and-error method may lead to inefficiencies initially. Reflecting on past experiences can help refine the decision-making process. Prioritizing the right characteristics ensures the mold aligns with project goals.

When you choose a lightweight mold, consider several key factors. The material type is crucial. Common options include silicone, plastic, or metal. Each has unique properties. Some materials are more durable but heavier. Others are flexible and easy to work with, but they might not hold up under heavy use.

Tip: Assess the intended use of the mold. Is it for single-use or multiple projects? This can guide your material choice. A mold for quick casts can be light and simple. For detailed designs, a sturdier option may be necessary.

Think about the mold's size and shape carefully. Larger molds can be cumbersome, while small molds may not achieve your design goals. Ensure the mold matches the scale of your project. Measure twice and cut once.

Tip: It's wise to prototype. Create a test mold first. This allows you to see if it meets your needs. Don't skip this step; it can save time and resources. Reflect on any issues that arise during this process. Adjust your choices accordingly.

When selecting lightweight molds, it's essential to understand the various types and their specific applications. Common types include silicone molds, polyurethane molds, and thermoplastic molds. Silicone molds are flexible and ideal for intricate designs. They work well for small batch productions, particularly in the art and craft sectors.

Polyurethane molds, on the other hand, offer a balance of durability and weight. According to a recent industry report, the demand for polyurethane in moldmaking has increased by 15% over the past three years. These molds are robust and suitable for industrial applications. They're often used in manufacturing components that require a precise finish and consistent performance.

Thermoplastic molds are gaining traction due to their lightweight properties. They can be reshaped and reused, making them cost-effective for certain projects. However, they may not always meet the durability needs of high-volume production. For instance, while they excel in low-pressure applications, they might struggle under extreme conditions. Understanding these nuances is crucial for selecting the right mold for your project.

Choosing the right material for lightweight mold construction can significantly impact your project's success. Various materials are available, each with unique properties. Understanding these options helps you make informed choices.

Common materials include fiberglass, aluminum, and composite resins.

Fiberglass is popular for its strength and flexibility. It allows for intricate designs. Aluminum molds provide excellent thermal conductivity but can be heavier.

Composite resins are lightweight and suitable for complex shapes. However, they may be less durable.

Tips: Consider the final product's weight. A mold that is too heavy can hinder the manufacturing process. Think about the production volume as well. High-volume projects benefit from durable materials. Assess your budget too. Some materials are more cost-effective but may not suit every project.

Experimenting with different materials can lead to unexpected outcomes. Sometimes, a less popular choice can provide the best results. Reflect on your needs and priorities during the selection process. This will lead to better decision-making.

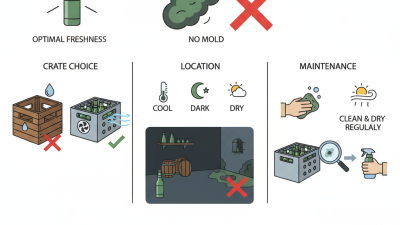

Choosing the right lightweight mold can significantly impact your project's success. Proper maintenance and usage are crucial. Here are some best practices to consider.

Regular cleaning is essential. After each use, clean the mold thoroughly to prevent residue buildup. Use warm, soapy water and a soft brush. Avoid harsh chemicals; they can damage the mold. Inspect the mold for wear and tear before each project. Look for cracks or deformities.

Tip: Keep a maintenance log. This helps track usage and identify patterns.

Temperature control is another critical factor. Lightweight molds can warp if exposed to extreme heat. Store them in a cool, dry place. Use protective covers during transportation; this reduces the risk of accidental damage.

Tip: Always follow the manufacturer’s guidelines. Adjust your techniques based on the specific material.

Experimentation is part of the process. Sometimes, molds behave unexpectedly; they may not release as easily as anticipated. Adjust your release agents accordingly. Don't hesitate to try different combinations.

Tip: Document your tests. This data can help refine your approach.