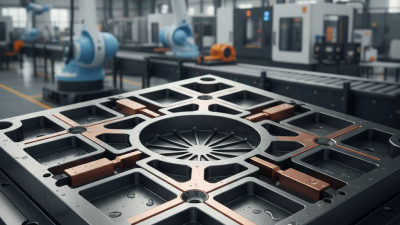

In the world of manufacturing, selecting the right Blow Molding Pallets is crucial. Renowned expert Jane Smith, who has over 20 years of experience in plastic production, states, "Choosing the right pallets can make or break your production efficiency." This highlights the importance of making informed choices.

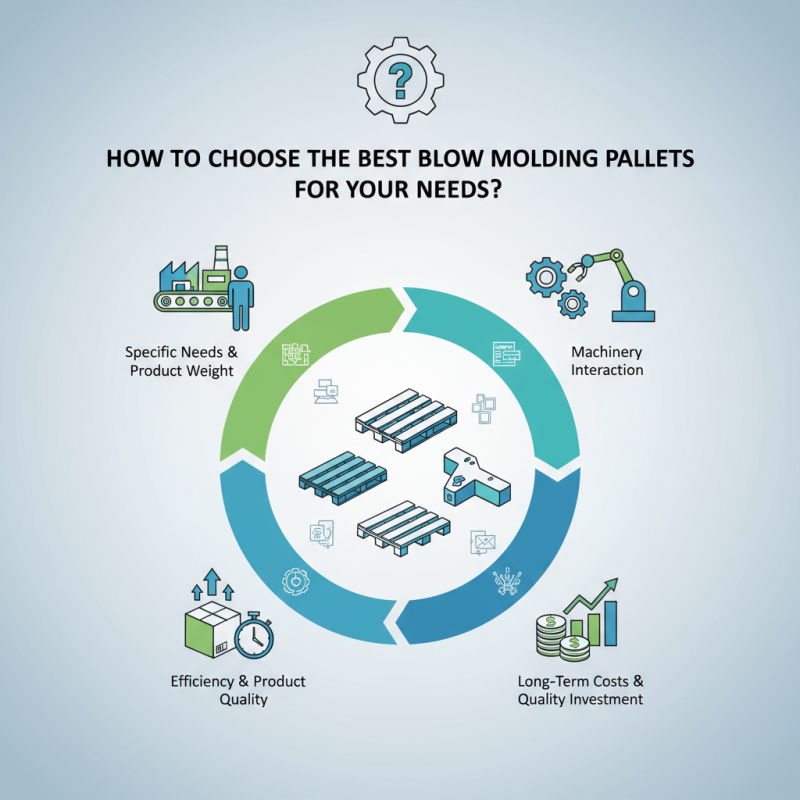

Blow Molding Pallets vary in size, material, and design. It is essential to consider your specific needs before making a decision. For example, heavier products require stronger pallets. Understanding how these pallets interact with your machinery can also influence your choice.

Many businesses overlook the long-term costs associated with pallets. Investing in quality can reduce damage and replacement needs over time. Reflecting on the unique aspects of your operation will lead to better outcomes. Ultimately, the correct Blow Molding Pallets enhance not only production efficiency but also overall product quality.

Blow molding pallets play a vital role in various industries. They are essential for transporting and storing products made through blow molding processes. The lightweight nature makes them ideal for handling. In 2022, the global blow molding pallet market was valued at approximately $3.5 billion, showing a steady growth expected to continue at a rate of 5.6% annually. This indicates their increasing importance in logistics and manufacturing.

Understanding the applications of these pallets is crucial. They are widely used in packaging, automotive parts, and household goods sectors. The design often caters to specific product types. For instance, some pallets are made to support heavy loads, while others are designed for efficiency in transport. However, not all pallets are created equal. Choosing the wrong type can lead to damage during shipping. It is important to consider factors like size, weight capacity, and material.

Evaluating your needs may take time. You might need to analyze the specific requirements of your operation. The dimensions of your products should dictate pallet size. Using a pallet that doesn’t fit perfectly can lead to wasted space. A report from the Pallet Manufacturers Association indicates 40% of pallets are incompatible with standard shipping containers. This statistic raises questions about efficiency within the industry.

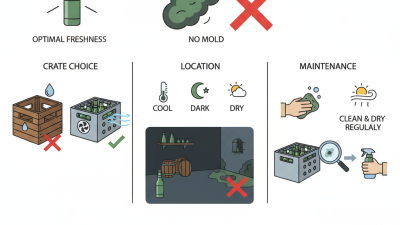

When selecting blow molding pallets, a few key factors matter greatly. Look at the weight capacity. Pallets should handle the specific loads of your operations. Overloading can lead to damage or accidents. The material of the pallets is crucial too. Different substances offer varying levels of durability and resistance.

Consider the size and design. Measure your equipment and storage space carefully. Pallets that are too large or small can cause inefficiencies. A well-sized pallet improves workflow and product handling. Think about the environmental impact as well. Some materials are recyclable, which is a plus for sustainability.

Don't forget about maintenance needs. Some pallets require specific cleaning processes. If overlooked, this can affect hygiene and functionality. In future decisions, reflect on your choices. The more you learn about blow molding pallets, the better equipped you will be.

When it comes to selecting blow molding pallets, material choice plays a crucial role. Common options include

high-density polyethylene (HDPE),

polypropylene (PP), and

polystyrene (PS). Each material has distinct characteristics that can affect the functionality and durability of the pallets.

For instance, HDPE is known for its strength and resistance to chemicals, making it suitable for various industrial applications. However, it might be heavier and less flexible than other materials.

Conversely, polypropylene is lighter and offers excellent impact resistance. This makes it a popular choice for lightweight products. Yet, it may not withstand extreme temperatures as well as HDPE.

Polystyrene is often more affordable, but it is less durable in high-stress environments, which can lead to frequent replacements.

Evaluating these options requires careful consideration of your specific needs. Think about the weight you will handle and the environmental exposure your pallets will face. Finding the right balance can be challenging. It's also important to reflect on your budget and long-term costs.

Sometimes, opting for the cheapest option can result in higher expenses down the line.

When selecting blow molding pallets, evaluating load capacity and durability is crucial. Load capacity defines how much weight each pallet can handle. If you guess too low, products may break. If you guess too high, pallets might fail. Typically, pallets have different ratings. Understanding your specific needs helps prevent mishaps.

Durability is another key factor. Consider materials used in pallet construction. Some plastics offer better resistance to chemicals and temperature extremes. Daily wear and tear will test pallets over time. You might overlook signs of damage, leading to costly errors later. Inspection is essential. Regular checks for cracks or deformation can save money and hassle.

Keep in mind that not every situation needs the most durable option. Sometimes, lighter pallets may be sufficient. However, it’s wise to err on the side of caution. Each application has unique demands. Reflecting on past experiences can inform better choices now. Balancing durability with load capacity is not always straightforward, yet it is necessary.

When evaluating blow molding pallets, cost-effectiveness is key. You will want to compare the price against the quality offered. High-quality pallets may seem more expensive initially, but they often prove to be more durable in the long run. Consider the materials used in the pallets. Stronger materials typically lead to fewer replacements and lower maintenance costs.

Finding the right supplier is crucial for getting the best value. Look for suppliers who have a strong reputation in the industry. Check their reviews and ask for recommendations. A reliable supplier can provide options that fit your specific needs. Don’t just settle for the cheapest option without considering quality. Sometimes, lower prices can lead to significant issues down the line.

Don’t forget about logistics. Shipping costs can add significantly to the overall price. Factor these into your budget as you assess options. Sometimes, less distance equals lower costs. However, it is also essential not to overlook service and support from suppliers. Good communication and customer service can save you headaches later.