In the world of manufacturing, "Cap Mold" plays a crucial role. This specialized mold shapes plastic caps, widely used in various industries. According to a report by Smithers Pira, the global market for plastic caps is projected to reach $31 billion by 2027. This growth emphasizes the importance of efficient manufacturing processes.

Cap molds are often made using precision engineering techniques. The materials used must withstand high temperatures and pressures during production. However, errors in the molding process can lead to defects, resulting in wasted resources and higher costs. A 2020 study revealed that nearly 15% of molded products are rejected due to flaws. This reflects the need for continual improvement in tooling and design.

Additionally, emerging technologies are impacting cap mold manufacturing. 3D printing, for example, offers new opportunities, though it isn't without challenges. Cost efficiency and quality control remain critical concerns. Manufacturers must adapt and innovate. The importance of Cap Mold in production cannot be overstated, as it directly affects product quality and overall industry success.

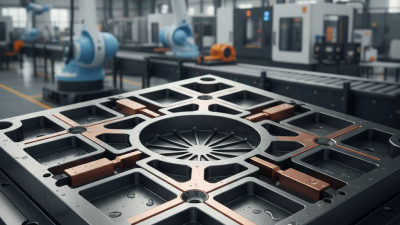

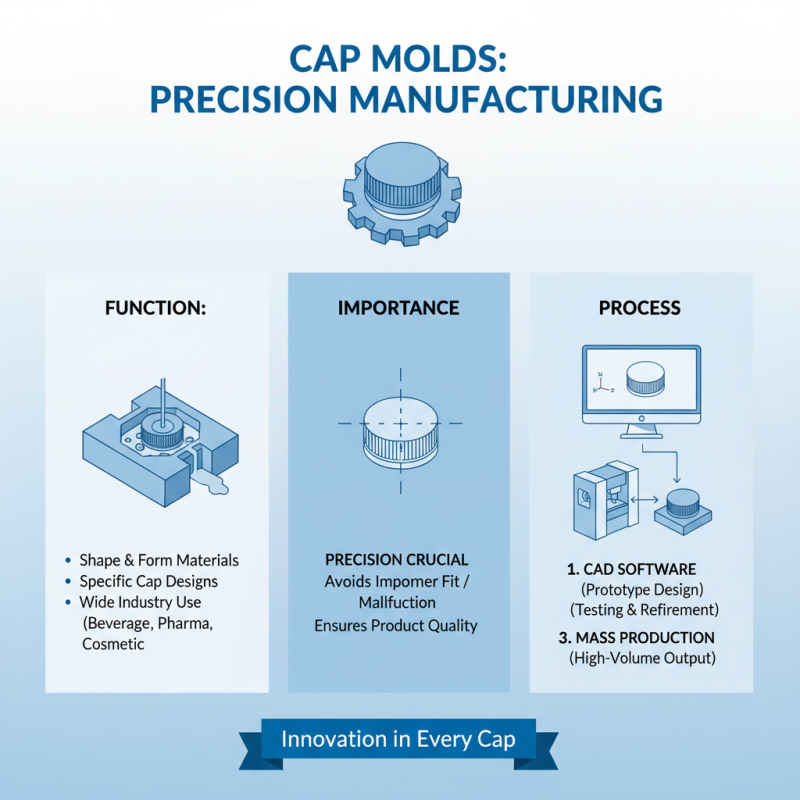

Cap molds play a crucial role in manufacturing processes. They are designed to shape and form materials into specific cap designs, used widely in various industries. The manufacturing of caps requires precision, as a slight error can lead to an improper fit or function. Manufacturers often create prototypes using computer-aided design (CAD) software. This ensures that every detail is accounted for before mass production.

In the molding process, molten materials are injected into the mold. The cooling phase is critical, as it affects the cap's strength and durability. If not cooled adequately, caps may warp or become fragile. Observing these outcomes helps in refining the mold design. Experimenting with different temperatures and materials can yield improved results. However, this process can be time-consuming and costly.

Additionally, maintenance of molds is essential. Wear and tear can affect their performance over time. Regular inspections are necessary to identify issues early. This reflects a commitment to quality in manufacturing. Manufacturers continuously seek to innovate and improve efficiency. Nonetheless, perfection remains elusive, making constant reflection on processes vital.

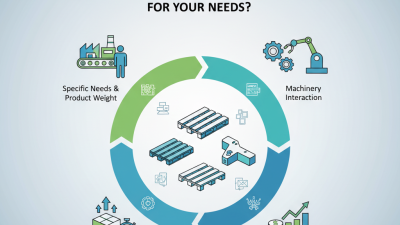

Cap molds play a crucial role in manufacturing. They are essential for creating various types of caps used in packaging. Different designs and materials are employed to meet specific industry needs. For instance, injection-molded caps often use high-density polyethylene (HDPE) or polypropylene (PP). These materials offer durability and resistance to chemicals. In 2022, the global cap and closure market was valued at approximately $45 billion, highlighting its importance.

Common designs include snap-on caps, flip-top caps, and screw caps. Each type serves a different purpose. Snap-on caps are typically easy to apply and remove. Flip-top caps provide convenience for dispensing liquids. Screw caps can ensure a tight seal, preventing leaks. According to industry reports, over 60% of packaging manufacturers prefer reusable and recyclable materials for sustainable production. However, some designs may struggle with user-friendliness, leading to frustration.

While many companies focus on efficiency, challenges remain. Quality control is vital, as defects in molding can lead to product failures. Additionally, cost considerations often limit innovation. Manufacturers need better solutions to balance cost, quality, and sustainability. There is room for improvement in design and material selection. Addressing these issues could enhance the overall functionality of cap molds in the industry.

Cap molds play a crucial role in manufacturing, particularly in the production of bottle caps and closures. These molds allow for precision and consistency, ensuring that each cap fits perfectly on its corresponding container. The use of cap molds helps streamline the production process, reducing waste and increasing output. Manufacturers can create multiple caps simultaneously, which saves time and resources.

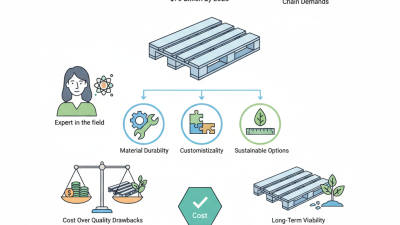

One key advantage of using cap molds is the ability to enhance production efficiency. These molds are designed for quick changeovers, making it easier to switch between different cap sizes or designs. This flexibility supports diverse manufacturing needs. Additionally, the high-quality materials used in cap molds can withstand repeated use, minimizing downtime for maintenance. However, the initial cost of investing in cap molds can be high, leading some manufacturers to hesitate. Exploring the long-term benefits is essential to make an informed decision.

While cap molds offer many advantages, there are also challenges. Over time, molds can wear out, impacting the quality of the caps produced. Regular inspection and maintenance are necessary to address this issue. Manufacturers must balance investment and upkeep to ensure optimal performance. Each production run might reveal areas for improvement. This reflection can drive innovation and better outcomes in cap manufacturing.

Cap molds play a crucial role in manufacturing processes, especially for products requiring precision and consistency. These molds shape the final products, ensuring accuracy in design and functionality. During production, each step can affect overall quality. If a mold has defects, it can lead to flawed products. This is why quality control is vital.

Industry standards guide the manufacturing of cap molds. They help maintain specifications that align with consumer expectations. Regular inspections during the molding process can catch errors early. However, not all manufacturers adhere strictly to these standards, which can result in variability. Some may overlook minor imperfections, believing they won't impact function. This assumption needs reevaluation.

Using advanced technologies in mold design can enhance quality. It's essential to invest in training staff about the importance of quality control. Understanding the nuances of the manufacturing process can prevent costly mistakes. Inconsistent adherence to standards can reflect poorly on the brand, so a proactive approach is necessary. Each mold should be treated with care to minimize errors and maintain a high level of production integrity.

Cap molds are essential in manufacturing applications, especially in the beverage and packaging industries. Recent innovations have focused on improving efficiency and precision. Advanced technologies have emerged, featuring enhanced cooling systems and quicker cycle times. These developments can reduce energy consumption and waste, but not all manufacturers have adapted effectively.

Tips: Regularly assess the cost-benefit of upgrading your cap mold technology. Sometimes, maintaining older systems can be more economical.

Moreover, automation is reshaping the cap mold landscape. Robotics in production lines increases consistency. However, the initial investment can be daunting for small businesses. Finding balance is crucial. Investment should align with production volume and specific needs.

Tips: Don't overlook employee training. A skilled workforce can bridge the gap between technology and effective production.

Looking ahead, sustainability in cap mold manufacturing is becoming a priority. Companies are exploring biodegradable materials and eco-friendly processes. This shift presents challenges for traditional mold designs. Innovations are necessary to maintain effectiveness while adhering to environmental standards.