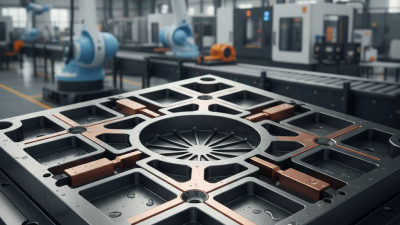

In the fast-paced world of manufacturing, efficiency is essential. The use of "Cable Tie Mould" technology is revolutionizing production lines. Industry expert John Smith, a renowned figure in mould design, states, “Each mould we create improves speed and consistency.” This highlights the importance of utilizing sophisticated cable tie moulds.

Cable tie moulds are specially designed for high-volume production. Their precision ensures that every cable tie produced meets stringent quality standards. This leads to reduced waste and lower costs. However, companies can struggle with initial setup and learning curves. The drive for perfection in production can often overshadow small imperfections in the process.

The benefits of these moulds extend beyond mere efficiency. They enhance product quality while increasing worker safety and satisfaction. The challenges in adapting to new technologies can lead to hesitance. Still, the potential rewards compel manufacturers to embrace change. Adopting cable tie moulds may pave the way for groundbreaking advancements in production methodologies.

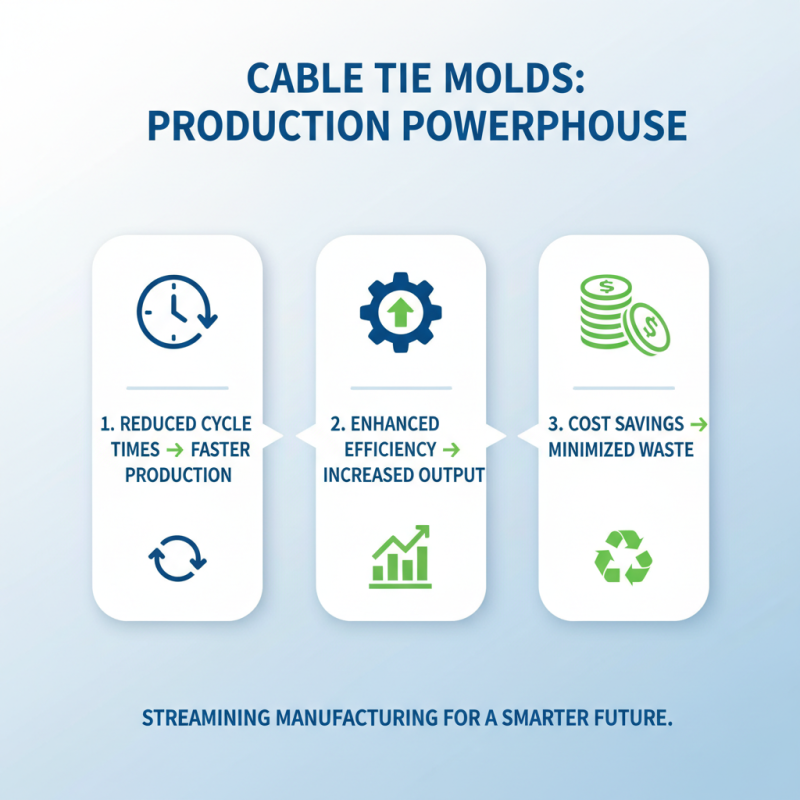

Cable tie moulds play a critical role in modern production. They help streamline production processes effectively. By reducing cycle times, they enhance overall efficiency. This allows manufacturers to increase output while minimizing waste. A well-designed mould can produce more items per hour. This efficiency translates to significant cost savings over time.

Additionally, using cable tie moulds reduces manual labor. Automation becomes easier, as consistent results are more easily achieved. Workers can focus on quality control instead of repetitive tasks. However, moulds themselves require careful maintenance and periodic inspection. A malfunctioning mould can disrupt the entire production line. Thus, manufacturers must invest in both quality and upkeep.

Moreover, moulds allow for customization. Various shapes and sizes can cater to specific needs. This flexibility can lead to innovative product designs. Yet, some manufacturers still struggle with adaptation. They may adhere too rigidly to traditional methods. Embracing new mould technology can be a challenge. Change often brings discomfort, but it is necessary for growth. The time spent exploring new solutions pays off in the long run.

Cable tie moulds bring a new level of precision to manufacturing. These moulds are crafted to ensure uniformity in cable ties. Every piece produced meets specific standards. This consistency reduces waste during production. When cable ties are uniform, they fit better and perform their intended functions more effectively.

Moreover, the design of cable tie moulds can impact production speed. A well-designed mould makes it easier to release ties without damaging them. This can save time and improve overall efficiency. However, flaws in mould design can lead to inconsistencies. Manufacturers must routinely inspect moulds to maintain quality. Often, this is overlooked, which can cause issues down the line. Regular checks can help avoid costly errors.

Using precise molds enhances the overall quality of cable ties. Improved quality reduces complaints and returns. Inconsistent products frustrate customers. Losing customer trust is a costly mistake. By focusing on precision and consistency, manufacturers can ensure a more reliable supply chain. However, they must also remain vigilant about their production processes. Quality assurance should not be an afterthought.

Cable tie moulds can significantly enhance efficiency in production lines. By offering precise designs, they minimize material waste. Every piece created using these moulds is tailored for optimal use. This precision leads to fewer defective products. Consequently, manufacturers save on both materials and labor costs.

Cost-effectiveness is evident when these moulds are employed. The initial investment may seem daunting. However, over time, the savings from reduced waste and faster production rates prove beneficial. Failing to invest in quality moulds can result in higher long-term expenses. Companies often overlook the cumulative impact of small savings.

Waste reduction remains a critical advantage. Using cable tie moulds reduces excess plastic that typically ends up in landfills. This process can be improved by re-evaluating production techniques too. While the benefits are clear, it’s essential for manufacturers to reflect on their practices. Constant improvement is necessary to fully harness the potential of these moulds.

Using cable tie moulds can significantly enhance production speed and efficiency. These moulds streamline the manufacturing process. Workers can create multiple cable ties in a single cycle. This reduces idle time and speeds up overall output.

Moreover, moulds allow for precise consistency in each product. This consistency minimizes defects and waste. However, setting up the moulds can be time-consuming. Some workers may face challenges during initial calibration. Training staff on proper usage is essential yet often overlooked.

While the benefits are clear, manufacturers must also consider maintenance. Regular checks are crucial to ensure optimal performance. Neglecting this can lead to delays and increased costs. Finding the right balance between speed and quality takes time and experience.

Cable tie moulds showcase remarkable versatility across various applications in manufacturing. These moulds allow for the rapid production of cable ties, significantly increasing efficiency. The ability to customize designs means they can cater to different sizes and shapes, fitting diverse needs. For instance, electrical, automotive, and even household sectors benefit from this adaptability.

Production facilities can quickly switch between different mould designs. This flexibility reduces downtime and enhances productivity. However, sometimes the changeover process may not be as smooth as anticipated. Workers might face challenges in aligning moulds correctly. Training is essential to minimize errors.

Another common oversight is the maintenance of the moulds. Regular checks are needed to ensure optimal performance. If neglected, the quality of cable ties can suffer, resulting in waste. Finding the right balance between efficiency and thorough maintenance can be tricky. Despite these challenges, the rewards of using cable tie moulds are substantial.

| Benefit | Description | Application Areas |

|---|---|---|

| Cost Efficiency | Reduces manufacturing costs by optimizing material usage. | Manufacturing, packaging |

| Speed of Production | Enhances production speed with quick mold setup and cycle times. | Automotive, electronics |

| Versatility | Can produce various sizes and types of cable ties. | Construction, telecommunications |

| Durability | Creates strong, durable products resistant to environmental factors. | Electrical, outdoor applications |

| Customization | Allows for customized designs to meet specific client needs. | Consumer goods, electronics |

| Reduced Waste | Minimizes material waste through precise injection molding technology. | Sustainable production |

| Enhanced Quality | Consistent quality assurance through automated processes. | Industrial manufacturing |

| Easy Handling | User-friendly design facilitates handling and application. | Logistics, warehouse |

| Safety Features | Integrated safety features prevent accidental injuries. | Construction, safety equipment |

| Market Demand | Increased demand for reliable securing solutions across sectors. | Global markets |