Heavy Duty Weight Molds are essential tools in various industries. Their robust design supports the creation of durable products. Many manufacturers rely on these molds for consistent quality.

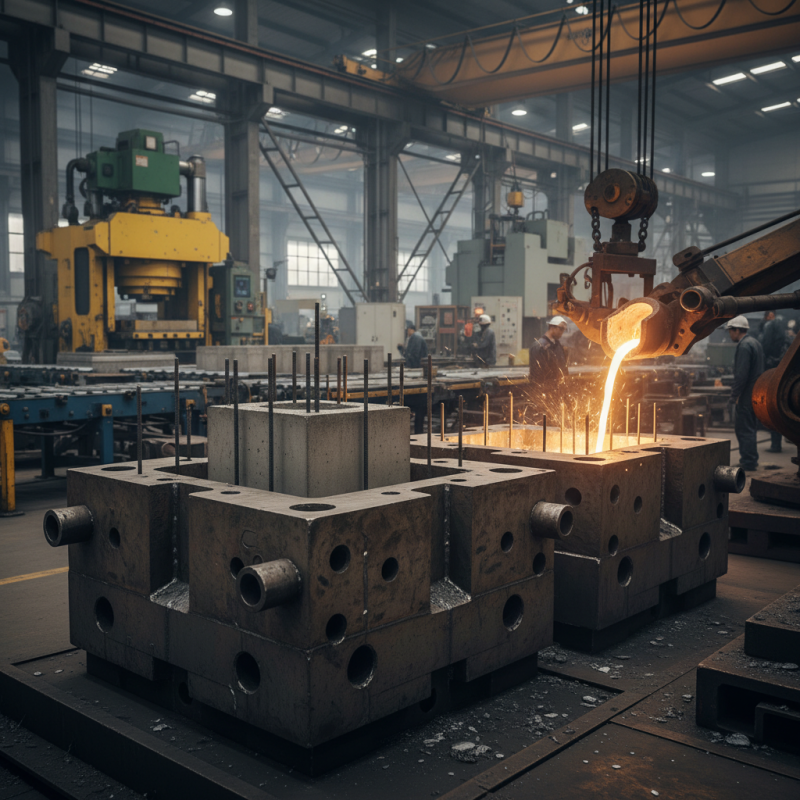

The applications of Heavy Duty Weight Molds span from concrete casting to metal shaping. They provide the ability to produce heavy components reliably. This versatility is crucial for industries demanding strength and precision.

However, not all manufacturers utilize these molds effectively. There can be challenges related to maintenance and proper usage. Understanding the benefits and learning from mistakes is vital. It is important to reflect on your processes to enhance productivity. Heavy Duty Weight Molds offer great potential when used correctly.

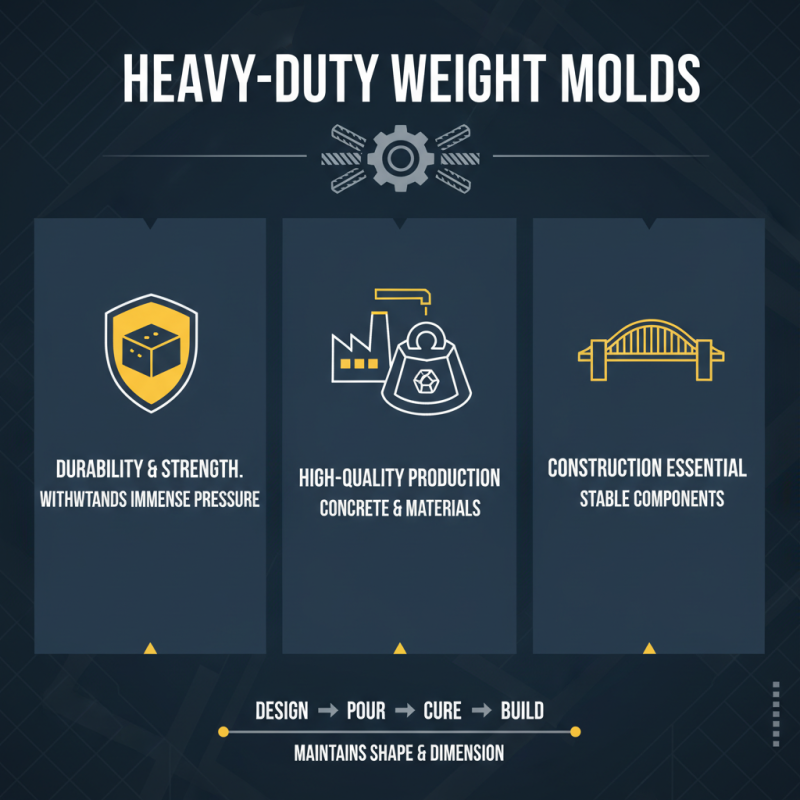

Heavy duty weight molds are essential tools in various industries. These molds are designed for durability and strength. They can withstand immense pressure and wear. This ensures high-quality production of concrete and other materials. The construction sector frequently employs these molds to create stable components. Their robust design helps in maintaining shape and dimension during curing.

Understanding the complexity and benefits of heavy duty weight molds is crucial. These molds can be customized for specific applications. They can be used for creating different shapes and sizes. Engineers often face challenges in balancing design and function. Some molds may require modifications over time. Not being adaptable can lead to inefficiencies.

In practice, these molds can also encounter defects. Imperfections may arise due to improper handling or environmental factors. It's essential to review molds periodically. This can prevent unexpected breakdowns. A proactive approach to maintenance pays off in extended mold lifespan. Careful monitoring helps in achieving the best results in production.

Heavy duty weight molds are essential tools in various production processes. These molds allow manufacturers to create robust and durable products. The materials used in heavy duty molds can withstand high pressures and temperatures. This quality ensures a stable and consistent output. One benefit is the increased efficiency in production. By using these molds, companies can reduce waste and save on material costs.

Another advantage is their versatility. Heavy duty weight molds can be used in different industries, from construction to manufacturing. They accommodate various shapes and sizes. This flexibility allows for customization, meeting specific project requirements. Workers often appreciate how these molds simplify the production process. However, there may be challenges in maintaining them. Regular inspections are necessary to ensure they remain effective.

Also, not all heavy duty molds perform equally. Some may wear down faster due to high usage. This can lead to production delays and increased costs. Companies need to invest in quality molds to avoid such issues. Reflecting on the customization options can reveal further opportunities. Each project may require different specifications, which adds complexity. Embracing this complexity can ultimately lead to higher quality outputs.

Heavy duty weight molds are crucial in various industries, especially for applications requiring durability. The choice of materials greatly affects the performance and longevity of these molds. Commonly used materials include steel, aluminum, and composite options. Steel is popular for its strength and resistance to deformation. It can withstand heavy loads and extreme conditions, making it ideal for tough applications.

Aluminum offers a lighter alternative. It’s easier to handle and can be designed for specific applications. However, it may not provide the same level of durability under certain conditions. Composite materials are gaining traction too, thanks to their corrosion resistance and versatility. These materials can be tailored to meet specific environmental challenges, but they come at a higher cost.

While these materials are effective, there are challenges in usage. Steel molds can be heavy and cumbersome, requiring careful handling. Aluminum can warp under excessive heat. Even composites, while resilient, may not perform well in all scenarios. Each material has its pros and cons. Manufacturers must carefully consider the specific requirements of their projects. Choosing the right material can significantly impact both production efficiency and product quality.

| Material | Benefits | Applications |

|---|---|---|

| Steel | High durability, excellent strength, and weight retention. | Construction, manufacturing, heavy machinery. |

| Aluminum | Lightweight, corrosion-resistant, and easy to cast. | Aerospace, automotive components, molds. |

| Concrete | Cost-effective, good compressive strength. | Foundations, architectural elements, heavy-duty weights. |

| Cast Iron | Excellent wear resistance and high thermal conductivity. | Piping, engine blocks, heavy equipment parts. |

| Polymer Composites | Versatile, lightweight with tailored properties. | Marine applications, sports equipment, industrial uses. |

Heavy duty weight molds are essential in various industries, including construction, automotive, and manufacturing. These molds create durable concrete components, offering significant benefits. According to a recent industry report, the global demand for heavy duty concrete molds is projected to reach $1.2 billion by 2025. This expansion highlights their critical role in infrastructure development.

In construction, heavy duty weight molds facilitate the production of precast concrete items. These items often have precise specifications, ensuring quality. The automotive sector uses these molds for efficient production of parts. A case study from a leading automotive manufacturer demonstrated a 20% reduction in production times when using optimized weight molds. This efficiency is key in today’s competitive market.

However, challenges exist. Not all molds perform equally well under varying conditions. Inconsistent material quality can lead to defects. A study indicated that about 15% of heavy duty molds faced issues related to premature wear. Companies need to invest in research and development to address these shortcomings. The focus should be on improving material resilience and longevity, ensuring molds meet the rigorous demands of diverse applications.

Maintaining heavy-duty weight molds requires careful attention. Regular cleaning is essential. After each use, remove residue to prevent buildup. A simple scrub with mild detergent can do wonders. Inspect the molds for any cracks or damage. Such issues can affect performance and safety.

Proper storage is also vital. Store molds in a cool, dry place to avoid premature wear. Elevated racks work well to keep them off damp surfaces. Using a protective cover can prevent dust buildup. If molds sit unused for long, check them periodically.

Additionally, using the right techniques is crucial. Pouring at the correct temperature helps achieve optimal results. Avoid rushing the process; this can lead to errors. Observe the curing time for the materials used. Overlooking these details can result in problems later. Attention to these practices can lead to better durability and efficiency.