In the fast-evolving world of manufacturing, the choice of the right Pallet Mould can significantly impact production efficiency. Today, companies face challenges that require innovative solutions. The improper selection of a mould can lead to delays, increased costs, and subpar products. Each manufacturing process has its unique needs, making it vital to evaluate options thoroughly.

For manufacturers, understanding different mould designs is essential. Quality Pallet Moulds can enhance output and reduce waste. A well-designed mould not only shapes the product but also affects the entire production line. For instance, certain materials may perform better under specific conditions. This complexity raises questions about mould adaptability and longevity.

However, not every Pallet Mould option is perfect. Some designs may lack the durability needed for high-volume production. Manufacturers must reflect on their choices and seek feedback from industry peers. Continuous improvement is key to achieving optimal results. In this landscape, the 2026 best Pallet Mould options will highlight innovations that seek to balance efficiency and quality.

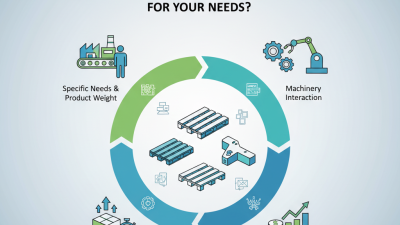

When it comes to pallet moulds, several distinct types are used in manufacturing. Each type serves specific purposes and can significantly impact production efficiency. Common types include injection moulds, blow moulds, and compression moulds. Injection moulds are favored for their precision. They can produce complex shapes with excellent detail, ideal for intricate designs. Blow moulds, on the other hand, cater to hollow parts. They are used frequently for packaging solutions. Compression moulds are generally more straightforward but limit design complexity.

Selecting the right mould type requires careful consideration. Many manufacturers overlook the potential for inefficiency in their choice. The wrong mould can lead to increased production costs and waste. For instance, using injection moulds for simple shapes can be over-complicating. They require longer cycle times and higher energy expenditure. It might also lead to higher maintenance costs over time. Experiments with different mould designs can reveal surprising results. Often, the best option isn't the most expensive one. Underestimating the impact of mould choice can hinder overall production quality and speed. Balancing cost and efficiency remains a continuous challenge in the manufacturing arena.

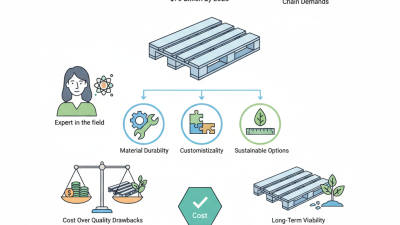

When selecting pallet moulds for efficient manufacturing, several factors play a key role. The type of materials used for moulds can significantly affect durability and production quality. Reports from industry analysts indicate that high-quality steel moulds can last up to five times longer than lower-grade options. This translates into reduced production costs over time.

Temperature tolerance is another crucial factor. Moulds must withstand varying temperatures during the manufacturing process. If the moulds are not designed for extreme conditions, they may warp or degrade. In fact, studies suggest that inconsistent temperatures account for 30% of mould failures in the industry. Ensuring your moulds can handle temperature fluctuations can mitigate risks and enhance performance.

Tips: Evaluate your mould designs and materials carefully. Consider using advanced materials that offer both strength and flexibility. Regular maintenance is essential to prolong the life of your moulds. Always track manufacturing data to identify trends or issues. This information is invaluable for informing future purchases and adjustments.

When choosing materials for pallet mould production, several factors come into play. The selection impacts durability, cost, and production efficiency. Common materials include steel, aluminum, and various plastics. Steel offers strength and longevity, but it can be heavy and expensive. Aluminum is lighter and resistant to rust, making it a practical choice. However, it may not always withstand extreme loads. Plastics are lightweight and corrosion-resistant, yet they might not provide the same strength as metals.

It’s crucial to assess the specific needs of your production line. Different projects may require unique mould characteristics. For heavier items, a steel mould might be essential. For lighter, more frequent production runs, consider plastic or aluminum options. Every material has its trade-offs. A heavier mould may slow down production, while a lighter option might wear out faster.

**Tip:** Regularly review your production goals. Keeping an eye on material performance can guide future adjustments. Consider the environmental impact too. Some materials may be more eco-friendly than others. Balancing efficiency with sustainability is vital. Reflect on what worked previously and be open to trials. Experimentation can lead to better efficiency.

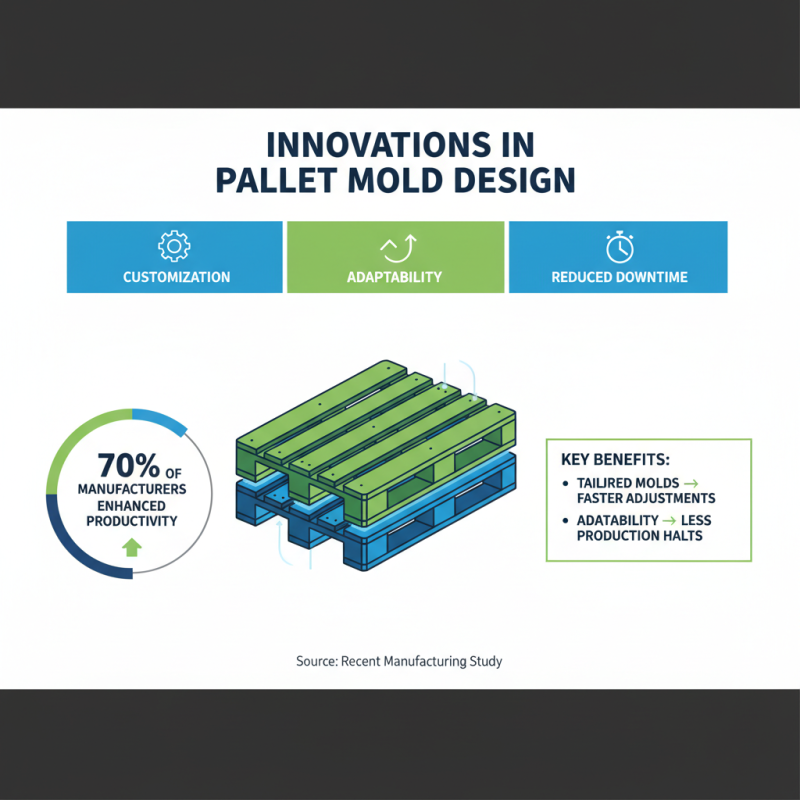

Innovations in pallet mould design are reshaping manufacturing efficiency. The focus is now on customization and adaptability. According to a recent study, 70% of manufacturers report that tailored pallet moulds enhance productivity. These moulds are easier to adjust based on specific production needs. This adaptability reduces downtime significantly.

Another critical aspect is the use of advanced materials. Research shows that 50% of companies are shifting towards lighter yet durable materials. This change leads to reduced energy consumption during the manufacturing process. However, striking a balance is essential. Not all new materials perform optimally in varying conditions. Some may falter under pressure, leading to unexpected failures.

Design innovations also include advanced cooling systems. Efficient cooling can enhance production speed by up to 30%. However, these systems require precise engineering. Any miscalculation can result in longer cycle times. Continuous improvement is crucial in this area. The drive for enhanced efficiency often exposes gaps in current methodologies. Reflection on these weaknesses can lead to more robust designs in the future.

The pallet mould industry is evolving. Technology trends indicate that automation will play a crucial role in manufacturing processes by 2026. According to a recent report, nearly 70% of manufacturers plan to adopt automated systems to improve efficiency. Automation reduces production time and increases consistency. It also minimizes human errors, which can be costly.

Sustainability remains a key focus. Eco-friendly materials are gaining traction in the pallet mould market. A survey revealed that 60% of manufacturers are shifting towards biodegradable composites. This shift reflects growing environmental concerns. However, the challenge is balancing durability with sustainability. Some materials may not perform well under heavy loads. Choosing the right material remains a topic for discussion.

Data analysis shows that energy-efficient moulding processes could reduce costs by 25%. Investing in energy-efficient technology can lead to significant savings. Yet, many manufacturers hesitate due to upfront costs. Risk-taking is essential for long-term gains, but it requires careful consideration. The path forward involves navigating these complexities while embracing innovation.