Premium Beer Crate Plastic Injection Mould from Trusted Manufacturers, High Quality

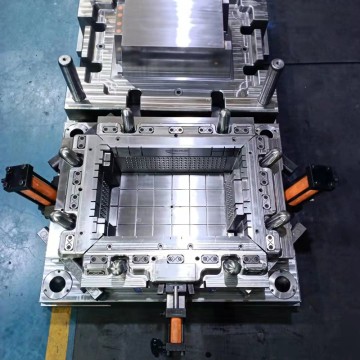

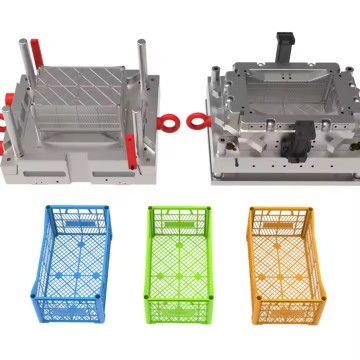

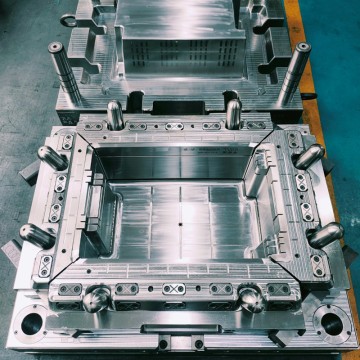

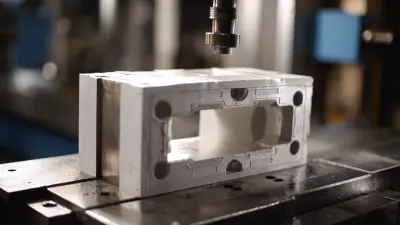

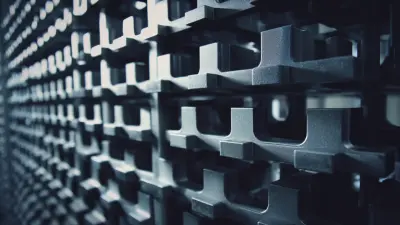

The Beer Crate Plastic Injection Mould stands out as a vital solution for the beverage industry, enhancing both efficiency and product quality. Our moulds are produced to the highest standards, ensuring each crate is tailored to your specific requirements. As a reputable manufacturer, we prioritize durability and precision in our designs, guaranteeing that our products can handle the rigors of daily use while economically managing production costs. With expertise in sourcing premium materials and maintaining meticulous production methods, our moulds are engineered for exceptional performance. Choosing our Beer Crate Plastic Injection Mould provides not just a product, but also a significant competitive edge in the market. Let's improve your packaging solutions together!

Best Methods To Beer Crate Plastic Injection Mould Your Trusted OEM Partner Manufacturers You Can Rely On

When it comes to sourcing high-quality beer crate plastic injection molds, selecting a trusted OEM partner is crucial for ensuring your product meets market standards and customer expectations. Our extensive expertise in various industries, including medical equipment, logistics, home furniture, and electrical appliances, positions us as a reliable manufacturer for businesses seeking customized molding solutions. We understand the unique demands of the beverage industry, and our advanced engineering capabilities allow us to create molds that are not only durable but also optimized for efficiency in production. We pride ourselves on partnering closely with our clients to understand their specific requirements. From concept to completion, our team works diligently to ensure that each mold is designed and manufactured to perfection. Our state-of-the-art technology enables us to produce innovative designs that enhance functionality while minimizing costs, making us an ideal choice for global buyers looking to tap into the booming beverage market. Trust us as your OEM partner, and experience unmatched quality and service that will streamline your manufacturing process and elevate your product in the marketplace.

Best Methods To Beer Crate Plastic Injection Mould Your Trusted OEM Partner Manufacturers You Can Rely On

| Method | Description | Advantages | Considerations |

|---|---|---|---|

| Cold Runner Moulding | Uses a cold runner system to minimize waste. | Cost-effective for large production | Higher cycle time |

| Hot Runner Moulding | Maintains material temperature to reduce waste. | Faster cycle times, reduced waste | Higher initial costs |

| Multi-Cavity Moulding | Multiple parts produced in one cycle. | Increased production efficiency | Complexity in mould design |

| Stack Moulding | Uses two mould halves stacked on top of each other. | Space-efficient and high productivity | Higher mould costs |

| Insert Moulding | Incorporates metal components within plastic parts. | Durability and convenience | Requires precise alignment |

Best Way To Choose Beer Crate Plastic Injection Mould Exceeds Industry Benchmarks Industry Giant

J

James Harris

Impressive quality! The professionalism exhibited by the customer support team made a significant difference in my overall experience.

09 May 2025

E

Evelyn Young

I am thrilled with the quality of this product! The after-sales staff were not only knowledgeable but also genuinely cared about resolving my queries.

31 May 2025

S

Scarlett Moore

Outstanding craftsmanship! The after-sales support was equally commendable, with staff who clearly knew their stuff.

30 May 2025

J

Joshua King

Impressive quality! The support staff followed through and ensured my satisfaction—very commendable!

27 June 2025

M

Maya Green

Fantastic quality! The continuous support from the after-sales staff made the process further enjoyable.

12 June 2025

A

Aria Walker

Excellent product quality! The after-sales support team provided outstanding service—very knowledgeable and accommodating.

06 July 2025