Advanced Plastic Dustbin Mould Production for Global Manufacturers

Product Description

Why Our Moulds Define the Next Generation of Dustbins:

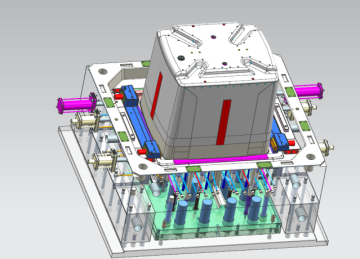

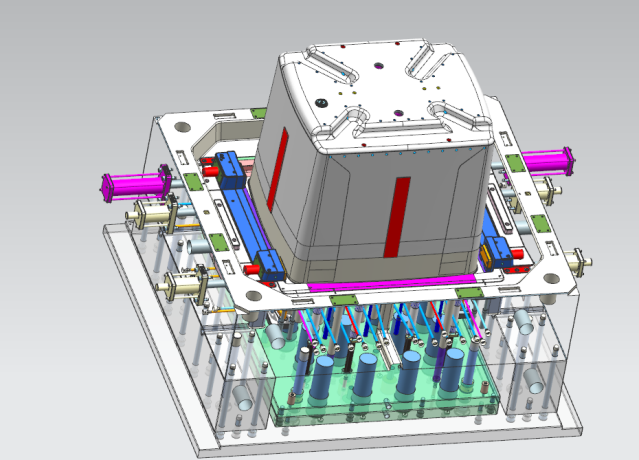

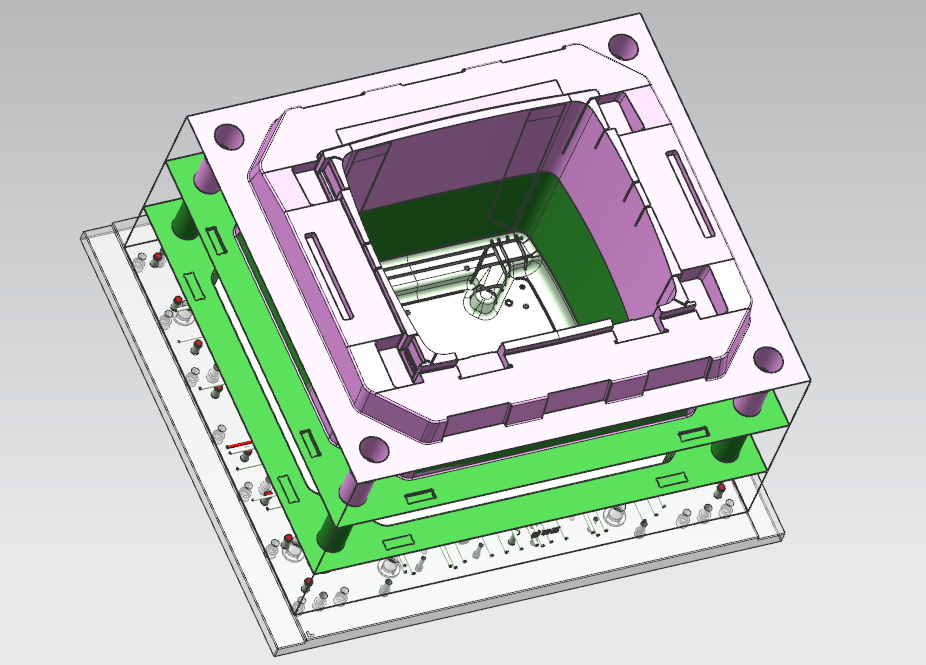

Optimized for Performance: Each mould is designed with an integrated cooling system and strategic gate placement to minimize cycle time and material stress, ensuring faster production and superior bin strength.

Designed for Lifecycle Value: We build for longevity with premium corrosion-resistant steels and standardized components, drastically reducing downtime and maintenance costs over the mould's lifetime.

Intelligent Customization: From sleek urban litter bins to heavy-duty industrial containers, our design team uses advanced flow simulation software to perfect your concept before cutting steel, mitigating risk and ensuring first-article success.

End-User Focused: Our designs incorporate subtle yet critical details—reinforced bases for impact resistance, ergonomic handles, and seamless surfaces for easy cleaning—creating dustbins that are not only durable but also preferred by end-users.

Your Partner from Concept to Container:

We are more than suppliers. Our process involves consultative collaboration, from initial design feedback and prototyping to on-site production support and after-sales service. We ensure your mould is an asset that drives profitability and brand reputation.

Let's build the foundation for better waste solutions, together.

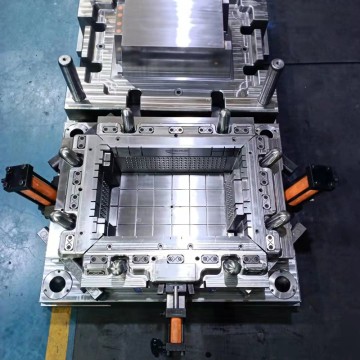

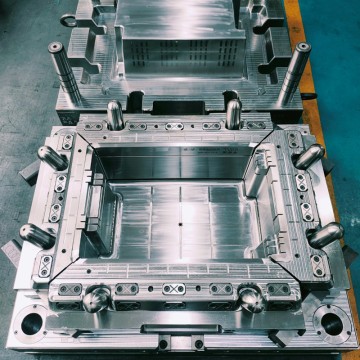

Workshop Images

FAQ

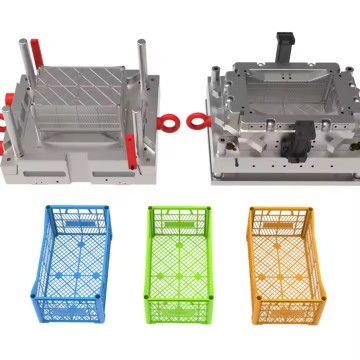

Household/Commercial series: pedal-operated bins, bins with inner liners, and recycling bins.

Municipal/Industrial series: large wheeled waste bins (120L-1100L), medical waste bins, and outdoor weather-resistant designs.

Customized designs: Capacity, structure (such as reinforcing ribs, anti-slip base rings), and surface texture can be adjusted according to customer needs.

Pre-hardened high-quality steel (P20/718H): Suitable for large-scale production of over 100,000 pieces per year, with a lifespan of over 1 million cycles.

Aerospace aluminum (such as 7075): Suitable for rapid prototyping and small-batch production, with high cooling efficiency and a lifespan of approximately 200,000-500,000 cycles.

All molds undergo nitriding or chrome plating surface treatment to enhance wear resistance and corrosion resistance.