Acrylic Chair Moulding Machine: Top Manufacturers and Suppliers for Quality Equipment

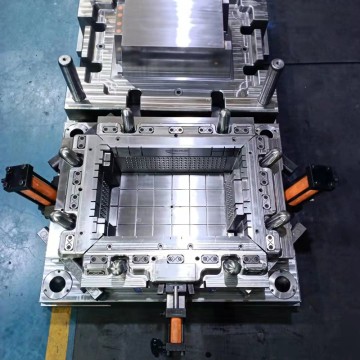

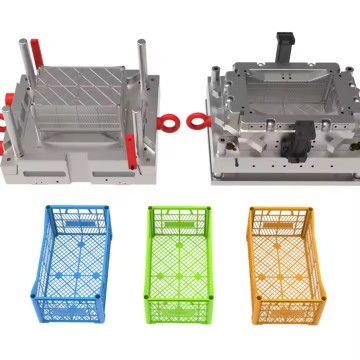

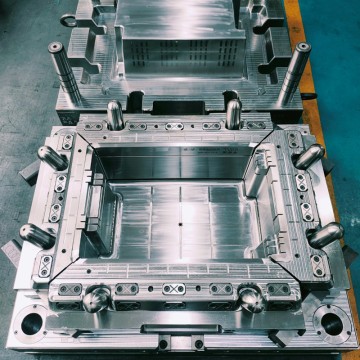

For high-quality Acrylic Chair Moulding Machine, partnering with a reliable factory is crucial for your production success. At Taizhou Huangyan Xintong Mold Co., Ltd., we focus on providing superior machines designed for longevity. Our acrylic chair moulding machines feature cutting-edge technology and exceptional craftsmanship, ensuring efficient and cost-effective manufacturing processes. With a commitment to quality, our machines go through thorough quality control, delivering excellent value for your investment. Suitable for businesses of all sizes, our solutions enhance performance and durability in your production line, resulting in outstanding end products. Contact us to learn more about how our acrylic chair moulding machines can improve your operations with a strong emphasis on quality.

Step-by-Step Guide Acrylic Chair Moulding Machine Trusted by Pros Application

In the competitive landscape of manufacturing, the demand for high-quality production equipment is paramount. One of the standout machines gaining traction among industry professionals is the acrylic chair molding machine. This step-by-step guide walks you through the essential aspects of utilizing this advanced machine, which has become a trusted ally for manufacturers across various sectors, including medical equipment, logistics, and home furniture. At the heart of its popularity lies the machine's ability to produce customized acrylic chairs with precision and efficiency. Our extensive experience in delivering tailor-made molding solutions enables businesses to achieve their design visions while maintaining optimal production standards. Whether you’re creating stylish seating for a modern workspace or durable fixtures for medical facilities, our acrylic chair molding machine adapts seamlessly to various applications, ensuring quality and durability in every piece produced. For global buyers seeking reliable partnerships, investing in dependable molding technology is a critical decision. Our commitment to innovation and excellence positions us as a foremost choice for companies looking to enhance their manufacturing capabilities. Explore the numerous benefits of our acrylic chair molding machine and join the ranks of professionals who trust us for their production needs, enabling your business to thrive in today’s dynamic market.

Step-by-Step Guide Acrylic Chair Moulding Machine Trusted by Pros Application

| Feature | Description | Application | Benefits |

|---|---|---|---|

| Precision Cutting | Allows for intricate designs with accurate measurements. | Used in creating modern chair frames. | Enhanced design flexibility and reduced waste material. |

| Fast Production | High-speed operation reduces manufacturing time. | Ideal for large batch productions. | Increased output and improved efficiency. |

| User-friendly Interface | Intuitive controls and easy navigation. | Suitable for operators of all skill levels. | Reduced training time and minimal operator errors. |

| Durability | Constructed with high-quality components. | Perfect for continuous, heavy-duty use. | Longer lifespan and lower maintenance costs. |

| Versatility | Capable of working with various materials. | Applies to different types of furniture. | Wide range of applications for diverse projects. |

Best Way To Choose Acrylic Chair Moulding Machine Ahead of the Curve For the Current Year

H

Henry Stewart

Exceptional quality! The after-sales service team provided thorough care, ensuring I felt supported throughout.

02 July 2025

J

Jacob Johnson

Exceptional quality! The care shown by the support team was evident as they diligently answered my inquiries.

28 June 2025

A

Aria Walker

Excellent product quality! The after-sales support team provided outstanding service—very knowledgeable and accommodating.

06 July 2025

K

Kinsley Edwards

Remarkable quality! The support team followed up swiftly and provided exceptional service.

03 July 2025

N

Nora Torres

The quality is great! I was very satisfied with the professionalism and helpfulness shown by the after-sales team.

16 June 2025

E

Ella Carter

Remarkable quality! I appreciate the professional after-sales support that was provided post-purchase.

23 May 2025